Tensile Surface Structures: A Practical Guide to Cable and Membrane Construction

Sign up for access to the world's latest research

Abstract

All rights reserved (including those of translation into other languages). No part of this book may be reproduced in any form -by photoprinting, or any other means -nor transmitted or translated into a machine language without written permission from the publisher. Registered names, trademarks, etc. used in this book, even when not specifi cally marked as such, are not to be considered unprotected by law.

Key takeaways

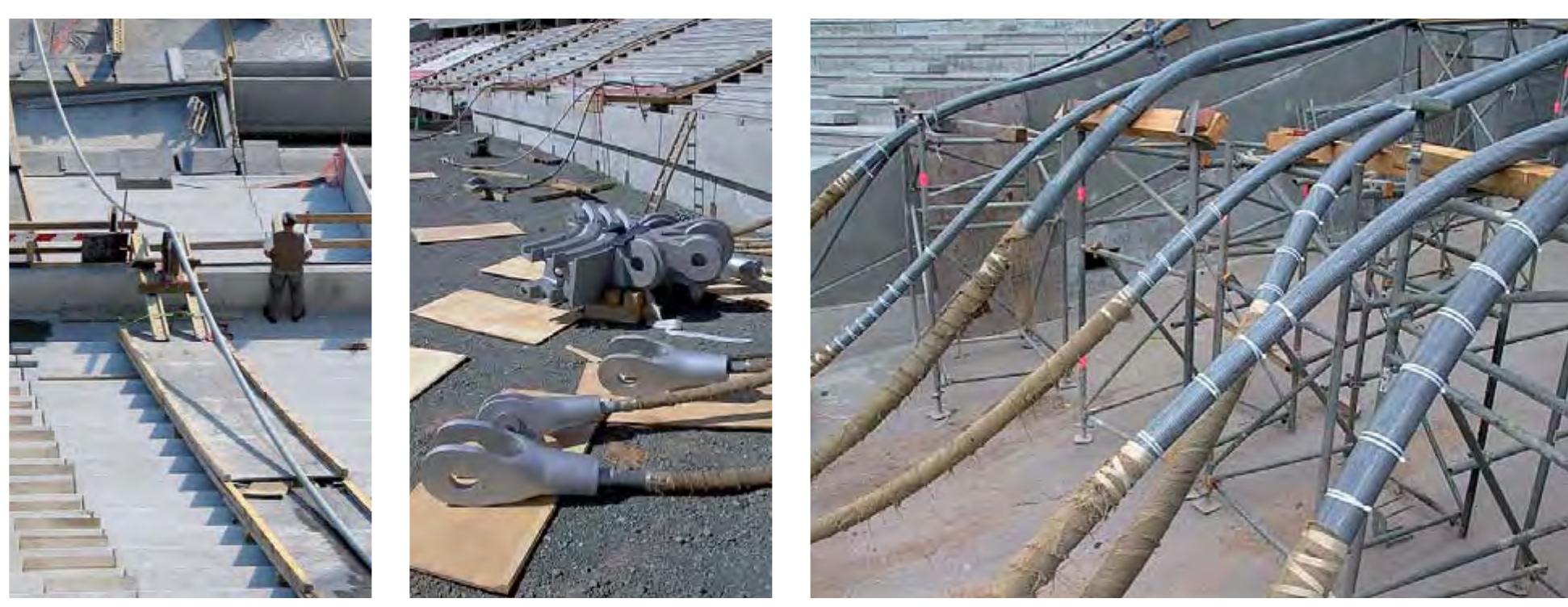

- During erection, a steel rope is pushed through as edge element (Fig. 131).

- This erection process can essentially be divided into the lifting and the tensioning of the rope.

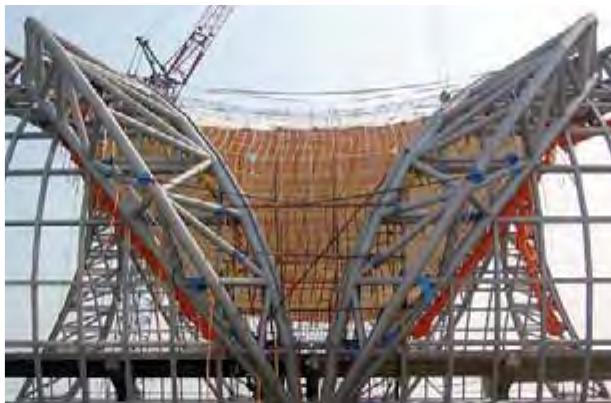

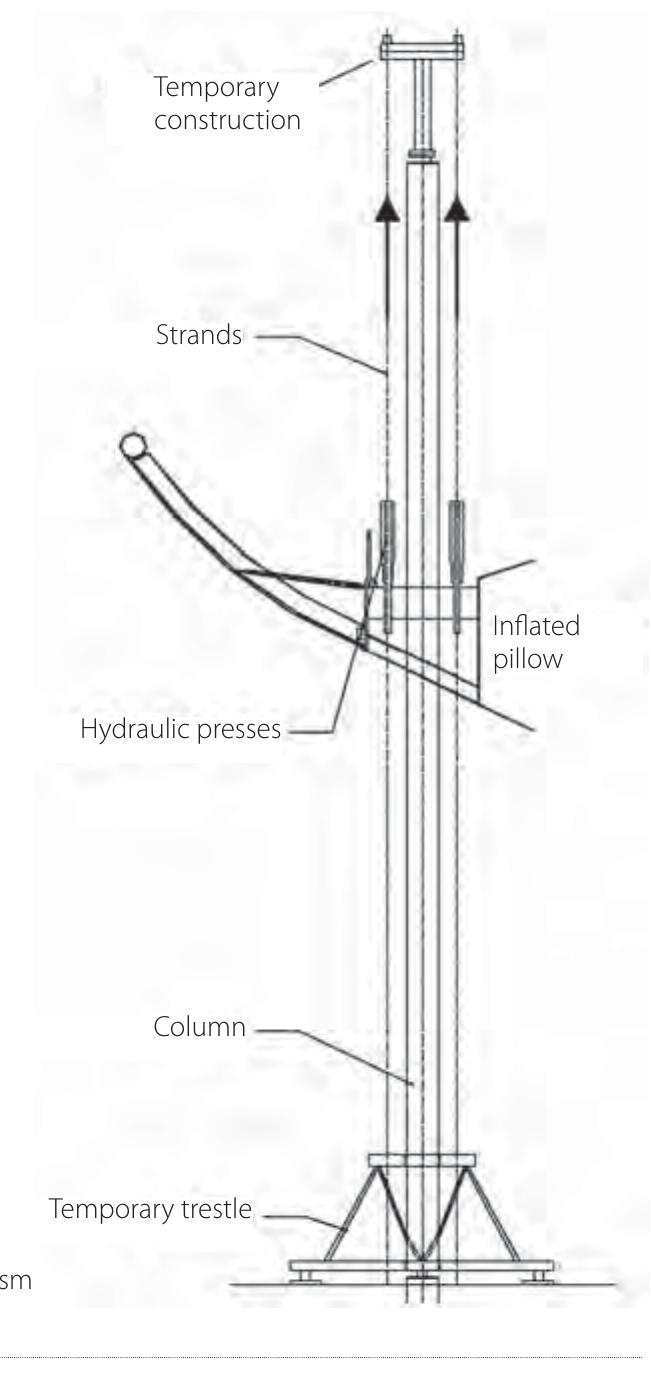

- After the erection of the perimeter rope bundle and the rope net has been laid out and preassembled, the radial ropes were lifted with strand tensioners over many weeks and bolted to the compression ring (Fig. 249).

- 4,000 m2 upper membrane 1 Habermann, K. J.;Schittich, C. (1994) The challenge of the initial erection was to lift the outer and inner layers of pillow and the rope net into position for tensioning without damaging the historic stands.

- This tensioning process is frequently used for the erection of awnings, where the fabric is pretensioned by the tilting of the masts and the shortening of the stay and edge ropes (Fig. 356).

Related papers

Steel Construction, 2015

This paper summarizes the differences in the design approaches for tensile surface structures between the earliest structures in the 1950s and today's practice. Current software tools allow more refined and advanced calculations. Nevertheless, a basic hand calculation can clarify the process in a few pages and provide the appropriate key data. A transparent setup allows the form-finding and structural analysis to be redone. The calculation of the cable net for the bandstand by André Paduart (1958) is analysed in this paper as a case study. Both the hand calculation (19 pages) and the numerical simulation are summarized and the design context of the initial and current calculations are described. The approximations made by Paduart resulted in a remarkably intelligible and coherent evaluation of the cable net structure. The historical approach can still be applied for a first verification of a pretensioned cable net or for a membrane structure as the simplified calculation method is similar.

This paper describes the numerical aspects of analysis of tensile structures including three principal types: membranes, cable-nets, pneumatic structures and combination of each other. In the first part, the base division and the survey of the form with examples are given. A brief historical perspective and development has been included too. In the next chapter of the article the problems of design and numerical analysis are presented. In the compact form the authors pay attention to the: shaping and form finding, selection of pretension forces in the initial configuration, the choice of constitutive models, the influence of boundary conditions and dynamic wind loads, the numerical tools of analysis' selection, the cutting pattern. Generally, these kinds of problems are the most common in the design processing of tension roofs. The note covers a summary discussion on these specify aspects with a lot of references to the literature in these interesting and developing branches of civil engineering.

Engineering Structures, 2012

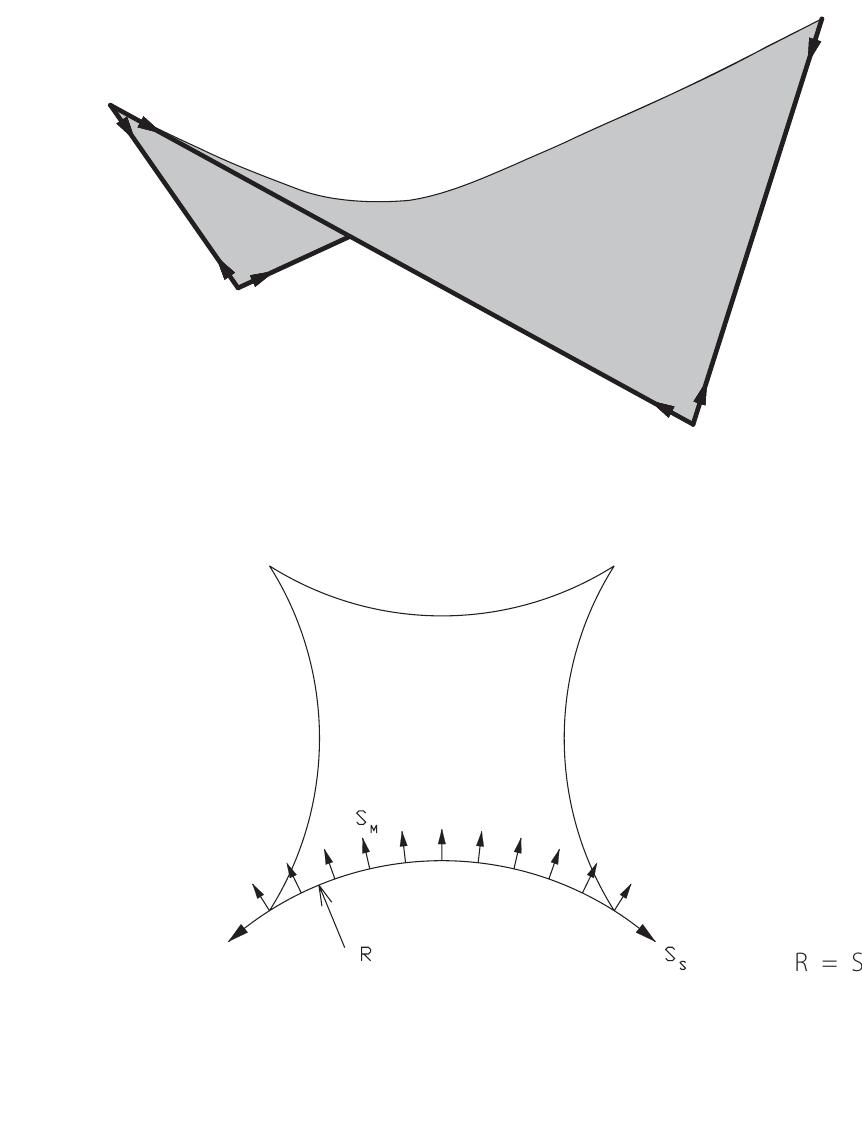

Coated woven fabrics have been used in state-of-the-art structures for over 40 years yet their design is not codified and relies heavily on experience and precedent. The mechanical behaviour of fabrics is non-linear and time dependent, with assumed or highly simplified material properties commonly used for analysis. The shape of a tensile fabric canopy is fundamental to its ability to resist all applied loads in tension. Increasingly Architects are moving away from conventional fabric forms, utilising lower levels of curvature and new materials. This paper considers the importance of material properties and structural geometry in the design and analysis of tensile fabric structures. Three typical tensile forms are examined: the conic, hyperbolic paraboloid ('hypar') and barrel vault. Whilst the barrel vault demonstrates the expected result that minimally curved structures are inefficient and highly sensitive to changes in materials properties, the hypar exhibits more complex behaviour with the structural action varying dramatically with changes in geometry, material properties and patterning (fabrication) direction. For conic structures the feasible geometries that can be attained using 'soap film' form-finding is established, which combined with checks for ponding provide a range of geometric parameters for the efficient design of conic structures.

2004

Current design considerations and practice for tensile fabric structures are discussed with reference to a recent project (Dalton Park, County Durham, UK). Non-linear fabric behaviour, large displacements and the use of membrane action to resist loads require a fundamentally different approach to structural design compared to traditional roof structures. The benefits to the design, manufacture, installation and maintenance of fabric structures to be gained from a better understanding of fabric material properties are considered. An ongoing programme of research at the University of Newcastle aims to thoroughly explore the behaviour of architectural fabrics, and to use this knowledge to improve design practice. Areas of research include biaxial testing of in-plane material properties 1 , creep, shear and the development of a reliability based analysis and simulated installation analysis.

Journal of Building Materials and Structures, 2020

Tensile structures represent a new chapter in the history of building structures. Tensile structure system are capable of spanning large distances while incurring very little weight on supporting structure, developments in the design of fabric structure can dramatically change the ways in which permanent building construction is conceptualized. This paper reviews the current methods and systems for design and construction of fabric structures. The paper begins with a brief historical evolution and explanation of the various types of fabric structure that have previously been built. Subsequent topics address the development of computational analysis methods, innovative construction techniques, fabric material types, properties and their characteristics. In this paper, a qualitative descriptive evaluation research method has been used. The research methodology comprises of case studies, visual observation and data collection. Finally, five case studies around the world have been presented to validate and illustrate the various modern trends and the direct application of design and construction methods of tensile structure system.

2015

Problems of computational mechanics related to finite-element analysis

2017

It is important to discuss and compare the rationale behind the success of the additive manufacturing technology in particular industries and at a particular scale versus full-scale building construction. The comparison should include structural qualities of the possible used materials, the cost effectiveness of the process, the time factor and its value in the construction process, the mass customization potential of the technology and its effect on building forms. The current state of technology in architecture, despite huge potential, has not produced new architectural forms.

Applied Sciences

Composite materials have been used in design since antiquity, as the description of the Ulises’ arch in the Odyssey suggests [...]

En: Symposium of the …, 2010

Proceedings of the International Association for Shell and Spatial Structures (IASS) Symposium 2009, Valencia Evolution and Trends in Design, Analysis and Construction of Shell and Spatial Structures 28 September 2 October 2009, Universidad Politecnica de Valencia, Spain ...

Engineering Solid Mechanics

Fabric Formworks which are made using textile sheets such as Polyolefin, Polyesters/Polyethylene Terephthalate, nylon and Polypropylene are being used instead of conventional formworks in the construction industry. This article summarises significant studies and provides an updated review of references on the structural performance of fabric formworks over the last decade. The survey showed that they could be categorised into seven themes; namely, "Feasibility studies and manufacturing methods of complex structural elements"; "Finite element modelling, structural optimizing and form-finding themes"; "Pneumatic / Vacuumatic formwork theme"; "Durability, sustainability, efficiency and quality improvement"; "Cable-net fabric formwork theme"; "Stayin-place structural formworks theme"; and "Review papers". These categories comprise about 25%, 17%, 15%, 15%, 10%, 6% and 6% of related studies respectively.

NA, 2021

This entire report is developed on the basis of the development of the system in which the proper utilisation of structural fastener selection can increase the efficiency of the structural lug design. The specification utilised for lug design to lift the clevis pin is fitted in the specific hole that offers to develop the strength and stress for the mechanical component. Is report is developed by conducting the research on the investigation for an existing method for the structural lug design, development of the numerical tool for assisting the designer in lug sizing and the investigation on the method and key consideration for structural fastener selection. This research has provided inane and several objectives on the basis of the research question. The literature review has been considered as the secondary data collection process by which the researcher can properly gather information for the topic. There are different themes which mainly utilised for collecting data on various aspects and all the aspects can be engaged by aligning the themes with the research objective. It helps to promote the proper validity and reliability of the research. The methodology has been considered on the basis of the requirements and utilises technology in which the functional and non-functional requirements has been noted while mentioning the hardware requirements software requirements and the used technology. The researcher mainly used MATLAB and Microsoft Excel as the major software to develop the simulation environment and describe the analysis. Regarding the result, the researcher has properly explained on the basis of the development of images from using different programming languages which can properly depict the efficiency of the structural design. Finally, the discussion chapter has also focused on the different themes that are mainly utilised in the literature review by which the alignment can be maintained on the entire research and concluded on the statement by answering the major research questions.

Tensile Membrane Structures - Form, Material and Design, 2019

Tensile membrane structures provide lightweight structure solutions and large spans can be covered quickly and economically using these systems. It offers rich, functional structural solutions with wide form and construction options. In some cases, structures that are not possible to realize by conventional construction techniques can only be constructed with the tensile membrane structure techniques. In this context, these systems have a content that broadens the concept of the structure. Lightness, flexibility, transparency, portability are characteristic features of this structures. Tensile membrane structures are constructed with elements that resist to the tensile load. However, a structure does not consist entirely of elements that only tensile resistant. The tensile loads on the membrane surface are transferred to the compression and bending resistant elements such as mast, beams, arch. Membrane structures differ from traditional building systems in terms of form and structural behavior. These systems show large deformation under external load. In order to eliminate the destructive effects of this deformation, there are specific principles that must be followed in the design phase. The aim of this thesis is to explain the basic design and analysis concepts of tensile membrane structures.

This paper showcases three recent projects from the design practice of Zwarts & Jansma Architects: an entry for the ARC Wildlife Crossing Design Competition, a design executed for the Extended Waal Bridge in Nijmegen, the Netherlands and HiLo, a research and innovation unit for NEST which is a flagship project of Empa and Eawag a collaborative effort to contribute to the future of construction. In all the three cases, the design has been driven by the construction method of using a large cable-net formwork with a secondary system of geotextiles. This new concept builds upon existing architectural vocabulary, ideas and advantages found in fabric formwork technology, cable-nets and tensioned membrane roofs, to allow for variable-scale, long-span structures. The resulting designs demonstrate the computational tools developed to imitate and inform physical realities and validate how both thin shell volumetric concrete structures can be made with this system. Both physical and digital, parametric design models were used during development of these designs. Insights into the feasibility and viability of this method have been discussed based on experiences during the design process leading to construction and realization in the real world.

Related topics

Loading Preview

Sorry, preview is currently unavailable. You can download the paper by clicking the button above.

Andres Labarca

Andres Labarca