This article deals with a summary of different fabrication methods of Aluminium Metal Matrix Composite (AMMC). This modern age demands the lightweight materials with very high strength, wear resistance, and corrosion resistance property... more

In this present research particulate reinforced aluminium metal matrix composite is developed by using sand mould and liquid stir casting processing route in which AA5052 reinforced with 5 wt. % SiC particulates of 63µm particle size. The... more

The weight saving requirement for automobiles has become more important, since the increase in the environmental issues. For boosting the fuel economy, maintaining safety and performance of modern automobiles; lightweight composite... more

The positive impact of nanoparticles on the behaviour of composite microstructures has been studied. These studies include the material characteristic features, the production methods, suitability with the other phases, surface area, the... more

In the present study, the nickel aluminide NiAl-based composite, reinforced with yttrium oxide Y2O3 with addition of titanium, was prepared by sintering at 1350 ° C for one and a half hours under an atmosphere of argon gas. Experimental... more

Your article is protected by copyright and all rights are held exclusively by ASM International. This e-offprint is for personal use only and shall not be self-archived in electronic repositories. If you wish to selfarchive your work,... more

Your article is protected by copyright and all rights are held exclusively by ASM International. This e-offprint is for personal use only and shall not be self-archived in electronic repositories. If you wish to selfarchive your work,... more

Grinding of metal matrix composites is a challengin g task on account of the hybrid nature of their constituents. In this study, the influence of grind ing process and parameters on surface finish and su rface integrity of MMC workpiece... more

When choosing a material for automobile piston components, be sure to choose one that satisfies all necessary specifications, like durability, resistance to temperature, and wear resistance. To achieve maximum efficiency and... more

Abstract—Forging, milling, turning, grinding and shaping etc. are the various industrial manufacturing processes which generate the metal waste. Grinding is extensively used in the finishing operation. The waste generated contains... more

The wear behaviour comparison of Al/SiC and Al/Al2O3 composites prepared by stir casting technique is investigated to find out the effects of weight percentage of SiC/Al2O3, load and the number of strokes on a reciprocating wear testing... more

The synthesis of magnesium silicon nitride (MgSiN 2 ) by direct nitridation of a Si/Mg 2 Si/Mg/Si 3 N 4 powder mixture is described. A nucleation period at 550°C and stepwise heattreatment schedule up to 1350°C was adopted for the... more

effect of Nb and C additions on the phase composition, microstructure, and creep resistance of Fe 3 Al-type alloys is investigated. Two alloys, which contained (at. pct) (i) 27.6 Al, 1.15 Nb and 0.19 C (Fe balance) and (ii) 27.1 Al, 1.11... more

FeAl-based MIL composites of various iron alloys were fabricated with an innovative "multiple-thin-foil" configuration and "two-stage reaction" strategy. Alternating stacked metal foils were reactive sintered via SPS at 600 o C and 1000 o... more

The risk of cracking/debonding of a cement overlay used to repair or strengthen an existing structure is still a key issue. Current bond test methods are not designed to measure the combined effect of peeling (mode I) and shear (mode II)... more

In this research, the mechanical properties (microhardness and wear) of Al-8Si-3Cu-2Zn nanocomposites with 0, 2, and 5% by weight of tungsten disulfide nanoplates have been investigated. The studied nanocomposite was produced through... more

In electrical discharge machining (EDM), a complete and clear theory has not yet been established. The developed theory (physical models) yields results far from reality due to the complexity of the physics. It is difficult to select... more

The use of agricultural residue has been considered an economic and environmentally friendly approach for development of aluminium composites. In this study, Al powder (Al) was reinforced with coconut shell ash (CSA), rice husk ash (RHA),... more

Light magnesium nanocomposites, offering great weight savings, have a great potential to be utilized in aerospace and automotive industries. They have also been attracted much attention to be evaluated as biomaterial recently owing to... more

The present investigation is aimed at studying the effect of dispersoid content and effect of chill on microstructure and mechanical properties of aluminum alloy (LM 13) hybrid metal matrix composites reinforced with garnet and fixed... more

The development of lightweight and high-performance materials has become a pivotal focus in automotive engineering due to the growing demand for energy-efficient and environmentally friendly vehicles. This research focuses on the use of... more

In this research, mechanical and microstructure properties of cold pressing (CP) and extrusion (EXTR) specimens produced via powder metallurgy were investigated and compared. For this comparison, EXTR specimens were hot extruded at 565°C... more

The rapid evolution of the mechanical industry necessitates reliable and innovative materials. Metal matrix composites (MMCs) have emerged as a leading contender for performing vital roles in this field. Carbon nanostructures, such as... more

This is to certify that the thesis entitled "Development of Cu-Based Metal Matrix Composites Using Silicon Carbide, E-Glass Fiber and Multiwalled Carbon Nanotubes as Reinforcement" being submitted by Mr. Harshpreet Singh to the National... more

This review paper investigates novel approaches to the fabrication of fiber-reinforced composites (FRCs) via additive manufacturing (AM), with a focus on improving mechanical properties in polymers, metals, and ceramics while reducing... more

Hybrid composites, specifically Al/SiC/Gr, are a promising area of research in material science. This work deals with the Al/SiCn/Grµ hybrid composite, which includes the additional nano silicon carbide particles (SiCn) at 2, 4, 6, 8, and... more

Neste artigo, será feita uma investigação sobre as maneiras pelas quais questões sobre imagem técnica são tematizadas em diferentes produções artísticas, usando como corpus de análise o filme Matrix, de Lana e Lilly Wachowski, e o romance... more

When choosing a material for automobile piston components, be sure to choose one that satisfies all

necessary specifications, like durability, resistance to temperature, and wear resistance.

necessary specifications, like durability, resistance to temperature, and wear resistance.

An motor cylinder's pistons are a critical part. The producers are compelled to investigate using the optimal piston alloy in the combustion chambers due to intense rivalry among them. The most common materials used to make pistons are... more

Ultrasonic waves with a frequency of 25 KHz were used to enhance the acidic chemical recycling of tungsten heavy alloy (WHA) scrap class 2 HA175 with a typical composition of Ni-5.25 wt%, Fe-2.25 wt%, and W-92.5 wt% to recover the... more

Manufacturing sectors, including automotive, aerospace, military, and aviation, are paying close attention to the increasing need for composite materials with better characteristics. Composite materials are significantly used in industry... more

The paper reviews contemporary research in the area of hybrid composites based on zinc and aluminium alloys reinforced with SiC and graphite particles. Metal matrix composites (MMCs) based on ZA matrix are being increasingly applied as... more

In the paper were shown the test results of tribological characteristics of hybrid composites with alloy base A356 reinforced by SiC and graphite. Hybrid composites are obtained by compo casting procedure. Tribological tests are realized... more

The use of general descriptive names, registered names, trademarks, service marks, etc. in this publication does not imply, even in the absence of a specific statement, that such names are exempt from the relevant protective laws and... more

The prominent demerit of aluminum as a food grade material is its low tensile strength and impact tolerance with greater liability to break compared to other common food grade metals. It is reaffirmed that aluminum can corrode appreciably... more

In this research, the microstructure and mechanical properties of Al-15Si-10Zn-xZrO 2 (x = 5, 7 and 10 wt.%) composites synthesized by the stir-casting process have been investigated. The matrix and composite samples were characterized... more

An motor cylinder's pistons are a critical part. The producers are compelled to investigate using the optimal piston alloy in the combustion chambers due to intense rivalry among them. The most common materials used to make pistons are... more

Effect of titanium addition on the dry sliding wear behaviour of hypereutectic Al-Si alloys are investigated at elevated temperatures. Wear tests are conducted for varying normal pressure from 0.20 N/mm 2 to 0.98 N/mm 2 , for varying... more

In this study, two erosion protection MMC coatings with WC particles were deposited by the plasma transferred arc (PTA) welding. One of the coatings with tungsten carbide WC in the NiBSi matrix (WC/NiBSi), and the second coating WC in... more

High stress abrasive wear behaviour of Al-Zn alloys containing high zinc concentration at varying applied load and abrasive size has been studied through two-level full factorial design approach. The upper level of zinc concentration,... more

This NIRT research program is to advance both the fundamental understanding and knowledge of ultrasonic cavitation based solidification processing of complex bulk Mg MMNC materials/components and their processing/structure/property... more

Tribology experiments have a crucial importance in order to verify results of simulations and calculations and sometimes it is the only way to solve important problems and tasks. Numerous requirements in experimental investigations now... more

#D printing of a continuous carbon fiber reinforced bronze-matrix composite using material extrusion

he main objective of this study is to investigate, for the first time, the feasibility of 3d printing a continuous carbon fiber (CCF) reinforced metal matrix composite using a cost-effective material extrusion (MEX) technology. Notably,... more

Nowadays sandwich structures are used as bird shields to protect aircraft nose bulkhead. They are usually made of aluminum honeycomb and sheets. In order to optimize mass, cost and efficiency of such bird shields, aircraft manufacturers... more

The process of machining CFRP composites presents unique challenges, particularly in the context of WEDM. The inherent properties of CFRP composites, such as their low electrical conductivity, anisotropic nature, and heterogeneous... more

In this research, mechanical alloying was used to synthesize ultrafine grained AA2024 and AA2024-B4C powders in an attrition mill under argon atmosphere up to 50 h with the rotational speed of 400 rpm. In order to determine the grain size... more

In this study, co-precipitation processing route has been opted to prepare the ZTA composites. The well homogenized powders are compacted in a circular shape die-punch arrangement using hydraulic press. The mechanical properties of... more

Wire Electrochemical Micromachining is a relatively new method of machining using electrochemical dissolution; it utilizes the principle of electrolysis and uses a micro-wire for metal removal to produce micro metal parts. Since there is... more

In this study, co-precipitation processing route has been opted to prepare the ZTA composites. The well homogenized powders are compacted in a circular shape die-punch arrangement using hydraulic press. The mechanical properties of... more

The fatigue behaviour of Aluminium alloy (LM4) � Alumina silicate (Al2O3SiO2) particulate composite is investigated in comparison with unreinforced LM4 aluminium alloy in this work. Four different volume fractions (0.05, 0.15 and 0.20) of... more

![Fig. 25. The electrical conductivity of carbon nanotube/copper composite material changes with the volume fraction of carbon nanotubes. Adapted from Ref. [169].](https://figures.academia-assets.com/120816709/figure_026.jpg)

![Fig. 26. Histogram with the coefficient of thermal conductivity « values for all considered cases. Adapted from Ref. [206].](https://figures.academia-assets.com/120816709/figure_028.jpg)

![Fig. 27. Vickers hardness and thermal conductivity of pure Cu, ball milling (BM) Cu-Gr and ultrasonication (US) Cu-Gr composites. Adapted from Ref. [211].](https://figures.academia-assets.com/120816709/figure_029.jpg)

![Fig. 28. Variation of tensile strength (a) and elongation (b) with the number of ARB cycles. Adapted from Ref. [216]](https://figures.academia-assets.com/120816709/figure_030.jpg)

![Fig. 30. The stress-strain curves obtained for graphene-Ni-MMCs. Adapted from Ref. [235].](https://figures.academia-assets.com/120816709/figure_032.jpg)

![Fig. 31. Multiscale analysis procedure of three-phase nanocomposite homog- enization. Adapted from Ref. [245].](https://figures.academia-assets.com/120816709/figure_033.jpg)

![Fig. 32. Dependency of the dynamic moduli E’ versus strain amplitude measured at room temperature. Adapted from Ref. [246].](https://figures.academia-assets.com/120816709/figure_035.jpg)

![Fig. 2. (a) and (b) BF-TEM of the composite structure and (c) and (d) HR-TEM of individual CNTs [34] Various techniques have been employed to fabricate Al-MMCs rein- forced with CNTs. One such technique involves using CNTs as rein- forcement with aluminum as the matrix to produce single matrix (SM) and dual matrix (DM) structures using the powder metallurgy technique [34]. The term "single matrix" refers to composites with a uniform ma- trix material, while "dual matrix" describes composites with two distinct matrix phases. Salama et al. [34] synthesized SM and DM samples of Al/CNT composites using the solid-state powder processing high-energy ball milling (HEBM) technique. Their research demonstrated that DM composites generally exhibit improved ductility compared to SM com- posites, albeit with a slight reduction in strength. However, the nano-indentation hardness and Young’s modulus of DM composites are quite similar to those of SM composites. Their results also suggest that the hardness of the reinforcing particles in DM composites depends on the CNT content and the interfacial region, which is influenced by the mixing ratio. High-magnification scanning electron microscopy (SEM) images revealed more ductile features in DM composites, attributed to the uniform distribution of reinforced particles as reported in Ref. [34]. The TEM images of an SM Al/CNT composite with 5 wt% CNT show the overall composite’s refined microstructure with grains ranging from ultrafine to the nanoscale (Fig. 2). The images also reveal clean and pore-free interfaces between the CNTs and the Al matrix, confirming a strong mechanical bond between both phases as a result of the ball milling process. Additionally, no CNT peak was observed at 2-theta = 26° in any of the samples (XRD patterns of SM and DM composite in Fig. 3), attributed to the uniform dispersion within the aluminum ma- trix. Other methods include multi-pass FSP [32,35], high-energy](https://figures.academia-assets.com/120816709/figure_002.jpg)

![Fig. 3. XRD patterns of SM and DM Al/CNT composite powders [34].](https://figures.academia-assets.com/120816709/figure_003.jpg)

![Fig. 4. Vickers hardness on CNT-rich and CNT-poor surfaces for various rota tion speeds. Adapted from Ref. [12].](https://figures.academia-assets.com/120816709/figure_004.jpg)

![Fig. 5. Nano CNT-reinforced ZA-27 composite hardness and porosity. Adapted from Ref. [7].](https://figures.academia-assets.com/120816709/figure_005.jpg)

![Fig. 6. IPF mappings of Al/1 wt% CNT composites after (a) 20 %, (b) 45 %, and (c) 90 % thickness reduction, (d) percentage of HAGBs, fraction of HAGBs (f HAGB), LAGB and HAGB average misorientation angles (0 LAGB, 9 HAGB), and HAGB spacing in the normal direction (d ND HAGB) in rolled Al/1 wt% CNT composites. Adapted from Ref. [57].](https://figures.academia-assets.com/120816709/figure_006.jpg)

![Fig. 7. Tensile strength for different Al-Si/CNT composites, with 0; 2; 4; and 6 wt% CNT [60].](https://figures.academia-assets.com/120816709/figure_007.jpg)

![Fig. 8. TEM morphological analysis for ASSC in the view of (a) matrix and CNT, SiC presence and (b) precipitation formed as Al,C3. Adapted from Ref. [63]. milling can help preserve the structure of the CNTs, improving the interfacial shear resistance and load transfer with CNTs wrapped in Al2O3. During processing, AlgO3 nanoparticles at the interface form, resulting in a complex CNT structure that effectively prevents sliding under tension. This enhances the transfer of load from the matrix to the CNTs. Furthermore, CNT clusters, resembling branches, that are con- nected to the surfaces of Al2O3 fibers could also enhance friction and prevent sliding at interfaces. CNTs’ ability to bear load and resist deformation is due to their high strength and stiffness. Nevertheless, an excessive amount of CNTs can result in clumping together and inade- quate bonding with the metal matrix, which may diminish the friction- enhancing benefits [64,65]. Fig. 9 illustrates critically how CNT/A- 1,03-enhanced AMCs behave mechanically. The stress-strain curves show that although reinforcements increase strength, they reduce ductility. There is an optimal concentration of CNT content for maximum strength, as exceeding it may lead to agglomeration and decreased performance. The strong connection between Al2O3 levels](https://figures.academia-assets.com/120816709/figure_008.jpg)

![Fig. 9. MMC compressive strength can vary with different preforms fabrication conditions: (a) strain-stress curves at 350 °C, (b) specimens with 2 % CNTs weight fraction, (c) 15 % Al2O3 volume fraction, and (d) 2 % CNTs weight fraction. Adapted from Ref. [64].](https://figures.academia-assets.com/120816709/figure_009.jpg)

![Fig. 11. SEM micrograph of A5G550 (a) 500X, (b) 1000X, (c) 2500X, (d) 3000X, (e) 5000X and (f) 10000X. Adapted from Ref. [18]](https://figures.academia-assets.com/120816709/figure_011.jpg)

![Fig. 12. Fracture morphology of the graphene/Al composites with different graphene content (a) Al; (b) 0.1 wt%Gr/Al; (c) 0.3 wt%Gr/Al; (d) 0.5 wt%Gr/Al. Adapted from Ref. [19].](https://figures.academia-assets.com/120816709/figure_012.jpg)

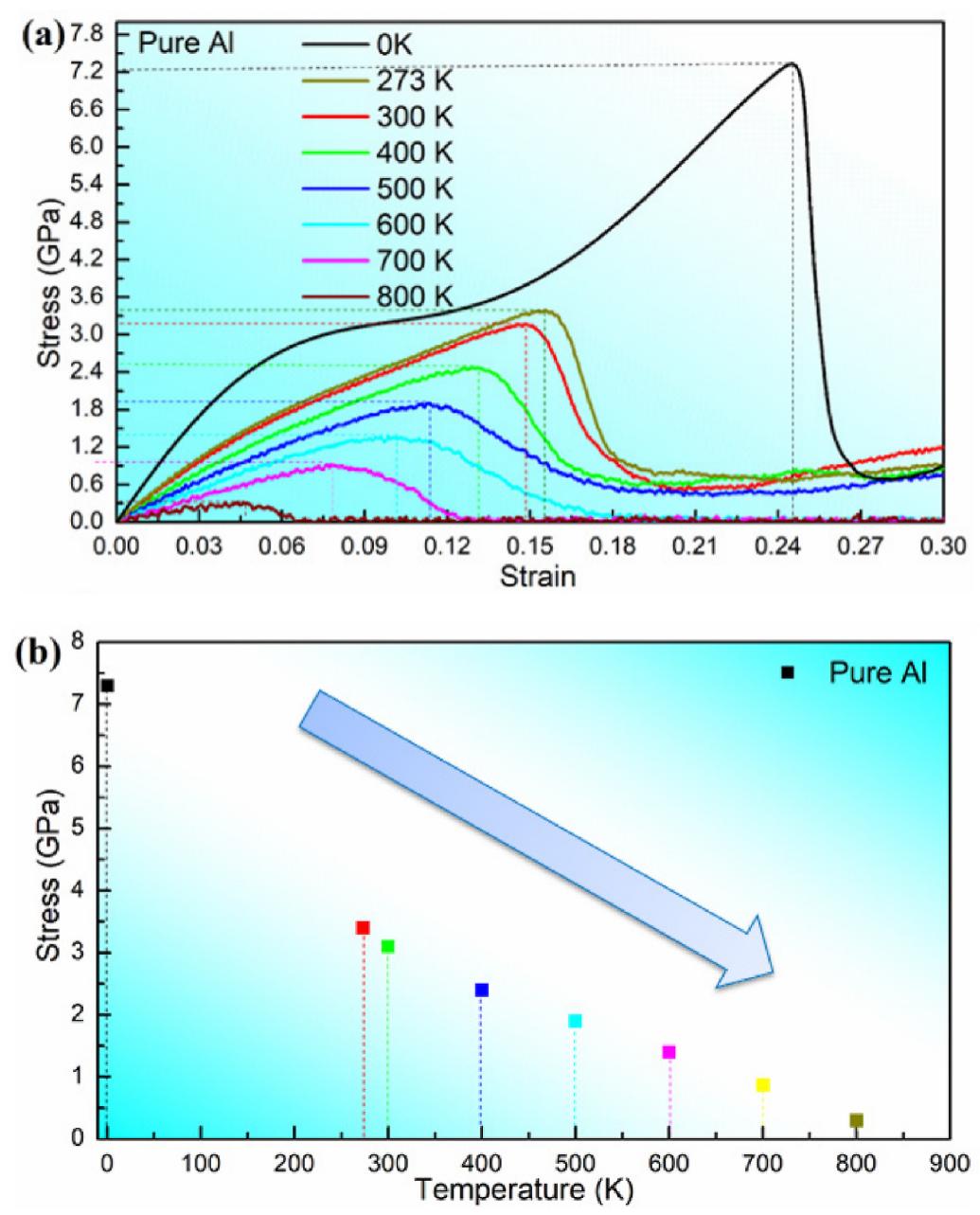

![Fig. 14. Break load against % graphene. Adapted from Ref. [24]. Fig. 13. Stress—strain curves (a) and values (b) of perfect aluminum substrate at different temperatures. Adapted from Ref. [99].](https://figures.academia-assets.com/120816709/figure_013.jpg)

![Fig. 15. Schematic representation for the development of Al-Si3N4-GnP composites. Adapted from Ref. [106].](https://figures.academia-assets.com/120816709/figure_015.jpg)

![Fig. 16. Tensile test stress-strain curves of AZ91 magnesium alloy, AZ91/1.0 mass% of CNT, and AZ91/1.0 mass% of SiC composites. Adapted from Ref. [118].](https://figures.academia-assets.com/120816709/figure_016.jpg)

![Fig. 17. Effect of CNT% on compressive properties of CNT/Mg composites: (a) typical true stress-strain curve; (b) strength and fracture strain. Adapte from Ref. [123].](https://figures.academia-assets.com/120816709/figure_017.jpg)

![Fig. 18. Grain size of CNTs/Mg composites prepared by Mg powder grinded for different times. Adapted from Ref. [125].](https://figures.academia-assets.com/120816709/figure_018.jpg)

![Fig. 19. A comparison of strain distributions and matrix projections at 0.2 % reinforcement strain Assuming (a) 2 jim length, 0.05 jm diameter, and 5 nm thicknes (b) The "unzipped GnP from the CNT" reinforcement measures 2 j1m in length, 0.05 ym in width, and 5 pm in thickness. Adapted from Ref. [26].](https://figures.academia-assets.com/120816709/figure_019.jpg)

![Fig. 20. Compression stress-strain curves of a) AZ61-based and b) AZ91-based composites and unreinforced alloys and c) compressive strength and ductility as a function of GNS ratio in the matrix. Adapted from Ref. [138].](https://figures.academia-assets.com/120816709/figure_020.jpg)

![Fig. 21. Variation of specific wear rate of the composites with additive content of reinforcement. Adapted from Ref. [141].](https://figures.academia-assets.com/120816709/figure_021.jpg)

![Fig. 22. (a) TEM image depicting dislocations present in the titanium phase, (b) HRTEM image illustrating a pristine MLG-Ti interface in a 0.5 wt% MLG/ composite, (c) and (d) SEM images capturing MLG-Ti interfaces in the 1.5 wt% MLG/Ti composite. Adapted from Ref. [154]. Table 10 (continued)](https://figures.academia-assets.com/120816709/figure_022.jpg)

![Fig. 23. Homogeneous Cu/CNT with superior mechanical properties than Cu fabricated by molecular mixing. Adapted from Ref. [167].](https://figures.academia-assets.com/120816709/figure_024.jpg)

![Fig. 24. Vicker hardness of Cu-CNT composites by nanoindentation. Adopted from Ref. [179].](https://figures.academia-assets.com/120816709/figure_025.jpg)

![Fig. 33. Tensile strength and modulus of modified DGEBF epoxy resin vs. content of MWCNTs. Adapted from Ref. [256]. According to a study [252], the addition of CNTs to PLA films at low ‘oncentrations through melt and solution compounding resulted in mproved conductivity, storage modulus, and crystallization behavior. ‘urthermore, a theoretical model suggested that the combination of PLA und CNTs would result in the formation of a three-dimensional onductive network owing to their one-dimensional structure and *xcellent dispersion, subsequently enhancing in-plane properties [253]. ‘used deposition modeling of 3D-printed composites of PLA containing | 28 nm-diameter, 2.5 pm-long CNTs showed a 30 % increase in Young’s nodulus at 5 % loading. However, the strength and toughness decreased 1s the CNTs were aligned along the extrusion [254]. The use of 3D srinting technology for segregated CNT/PLA composites has resulted in 1 notable increase in electromagnetic interference shielding effective- 1ess, reaching up to 67 dB. Furthermore, this approach has led to snhanced bending and Young’s modulus, which enable the production of tunable designs [255]. The introduction of 1 wt% MWCNTSs into ‘omposites of flax fiber-reinforced polymer resulted in a significant nhancement of its tensile strength by 48.7 % and modulus by 25.2 %, hile glass transition temperature increased by 10.68 K. This mprovement can be attributed to the high aspect ratio, strength, and nterface with the matrix, as demonstrated in Fig. 33 [256]. The inclu- ion of CNF into PLA has been reported to enhance thermal stability and nodulus, while CNF-reinforced PLA has demonstrated easier crystalli- ation [257]. Carboxylic acid-functionalized MWCNTs have been found o act as nucleating agents, enhancing the crystallinity and stability of LA for thermal oxidation and biodegradation resistance when](https://figures.academia-assets.com/120816709/figure_036.jpg)

![Fig. 34. The mechanical properties of collagen-CNT fibers and collagen fibers. Adapted from Ref. [261].](https://figures.academia-assets.com/120816709/figure_037.jpg)

![Mechanical properties of the composites [264]. Fig. 35. Ultimate tensile strength of flax fiber-epoxy hybrid biocomposites with different wt% of CNTs. Adapted from Ref. [265].](https://figures.academia-assets.com/120816709/figure_038.jpg)

![Fig. 36. (a-c) Tensile strength analysis of composites. Adapted from Ref. [276].](https://figures.academia-assets.com/120816709/figure_039.jpg)

![Fig. 37. The Young’s modulus and tensile strength of untreated, new fiber architecture, alkali-treated, and graphene material-coated composites using Flax, E-gla: and S-glass fiber composites were compared. Adapted from Ref. [284].](https://figures.academia-assets.com/120816709/figure_040.jpg)

![Fig. 38. Collected S-N data (a) and the number of cycles to failure per loading ratio (b). Adopted from Ref. [285].](https://figures.academia-assets.com/120816709/figure_041.jpg)

![Fig. 39. (a) Strength of flax/graphene/epoxy composites; (b) contribution of nanographene. Adapted from Ref. [299] For polymer matrix composites, judicious CNT and graphene inclu- sion realize noteworthy multi-functional upgrades across diverse matrices like PLA, epoxy, HDPE, and chitosan. Through experimental optimization, researchers have achieved impressive results, such as a strength of up to 2.49 MPa in starch-aloe bioplastics with just 0.045 wt% of graphene. Computational modeling has also proven useful in After analyzing the information provided, it can be concluded that graphene-based biocomposites have shown improvements in mechani- cal strength, electrical conductivity, thermal stability, and biocompati- bility. The incorporation of graphene has been observed to enhance the](https://figures.academia-assets.com/120816709/figure_042.jpg)

![Properties of various reinforcements [1]. Table 1](https://figures.academia-assets.com/120816709/table_001.jpg)

![Hardness for the Al/CNT and Ni/CNT nanocomposites reinforced with different contents of CNTs [54].](https://figures.academia-assets.com/120816709/table_002.jpg)

![Table 3 (continued) matrix, which has two-dimensional graphene sheets made of sp?-hy- bridized carbon atoms. Adding graphene to AMCs promotes homoge- neous distribution and interfacial bonding, improving their mechanical properties. However, the influence of adding graphene on the Al-Cu and Cu-GNP boundaries. These interfaces are referred to as creating "a strong connection between the particles of the composite material, increasing the strength of the composite" [81].](https://figures.academia-assets.com/120816709/table_008.jpg)

![Vickers hardness, the yield stress of pure Al and Al-GnP [84].](https://figures.academia-assets.com/120816709/table_009.jpg)

![Thermomechanical and mechanical properties of graphene/Al MMC [89]. Values in the parenthesis are the standard deviations. * average of five measurements at 250 °C. > average of four specimens. Table 5](https://figures.academia-assets.com/120816709/table_010.jpg)

![Table 6 (continued) incorporation of CNTs is also found to inhibit detrimental Si precipita- tion during processing [122]. The research indicates that the distribu- tion of CNTs within magnesium matrices is most effective when the CNT content is kept below 1 wt%. At higher levels, CNT clustering can lead to a reduction in both strength and ductility, as illustrated in Fig. 17 [123, 124]. As the increase in CNT content increases, the yield strength, ul- timate compressive strength, and fracture strain of composites all first increase and then decrease (Fig. 17). In addition to the benefits mentioned earlier, CNTs coated with copper, nickel, or other metals improved the interfacial bonding between reinforcements and matrix [123,125]. The coated Ni in CNTs reacts with the Mg matrix and form Mg>Ni, drastically enhancing interface bonding. This, along with the diffuse distribution of Mg2Ni throughout the matrix, significantly strengthens the CNT/Mg composite [123].](https://figures.academia-assets.com/120816709/table_014.jpg)

![Mechanical properties of AZ61 and AZ91-based composites and unreinforced alloys [51].](https://figures.academia-assets.com/120816709/table_015.jpg)

![Table 11 (continued) commonly used in thermal and electrical applications due to their high strength, excellent heat transfer, and corrosion resistance. These prop- erties can be further improved by adding CNTs to the copper matrix [167,168].](https://figures.academia-assets.com/120816709/table_021.jpg)

![Test matrix for laboratory experiments [251]. Table 16](https://figures.academia-assets.com/120816709/table_031.jpg)

![Compositions of the composite specimens in wt% [264].](https://figures.academia-assets.com/120816709/table_032.jpg)

![Composition of composites [276].](https://figures.academia-assets.com/120816709/table_034.jpg)