Plasma etch is a complex semiconductor manufacturing process in which material is removed from the surface of a silicon wafer using a gas in plasma form. As the process etch rate cannot be measured easily during or after processing,... more

The effect of Fe, Cu, Zr, and Ti substitution on magnetic properties of SmCo 1 : 7 magnets at temperatures up to 500 degreesC were studied. As-milled amorphous Sm(Co,Fe,Cu,Ti-Zr)(7) magnets crystallized in the TbCu7-type structure after... more

Sporting shoes, in particular those for running, must fulfill two requirements: on one hand they must assure the maximum utilization of the biomechanical energy, while on the other hand they must protect the athlete from functional... more

Simulation modelling has been identified as one of the most powerful techniques available for the analysis and design of complex manufacturing systems. A number of manufacturing simulators have been designed in an effort to make it easier... more

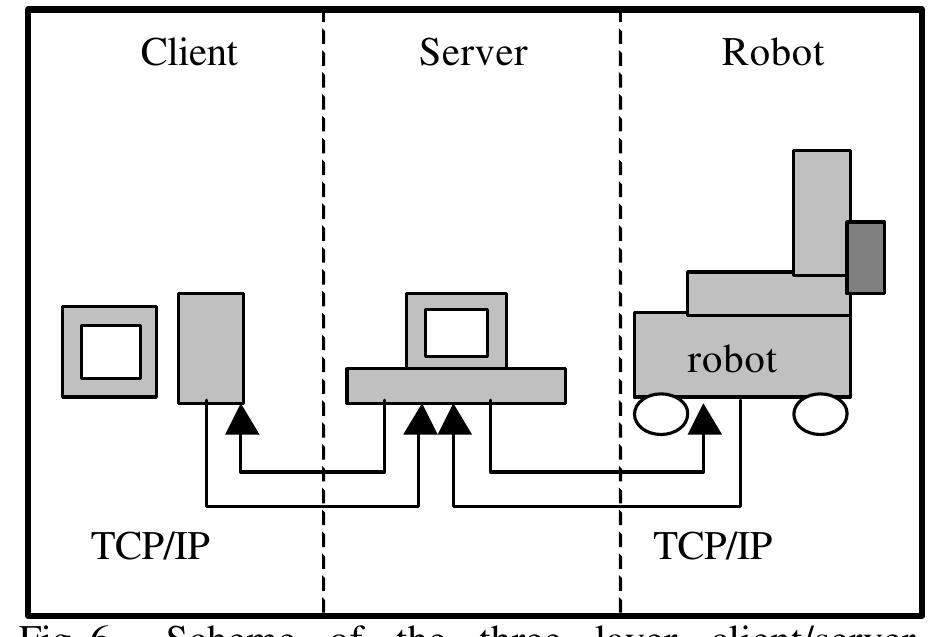

In this paper we intend to recreate an interactive 3D virtual version of the real environment of a mobile robot and to ensure a bi- directional interaction with all the components of this workplace. This IVW ( interactive virtual world),... more

This paper introduces and describes a mechanism for manufacturing robotic arm like human arm and its control method. At first a mechanical design of this robot that is inspired by a demonstration of the exact dimensions of its fingers is... more

Modular and Reconfigurable Robots (MRR) are a breed of industrial robots designed for today’s flexible and versatile production facilities. MRRs can be assembled in various ways to achieve numerous distinct Kinematic configurations (KC).... more

In this paper, an analytical modeling has been carried out to realize the effect of appending a supplementary percussive load to the rotary energy of tunnel boring machine's disc cutters, as a novel technology. In this path, two models... more

Product design engineering is undergoing a transformation from informal and largely experience-based discipline to a science-based domain. Computational intelligence offers models and algorithms that can contribute greatly to design... more

There are p heterogeneous objects to be assigned to n competing agents (n > p) each with unit demand. It is required to design a Groves mechanism for this assignment problem satisfying weak budget balance, individual rationality, and... more

Most of today’s environmental policies in Brazil rely on controlling the growth of pollution by “command and control” techniques. During the last two decades, these instruments have been designed to control sources of environmental... more

An Engineering Employers Federation report recently stated that US-owned manufacturers in the UK are gaining a competitive advantage through greater application of lean manufacturing. Brian Swain and Alan Mossman of Rubicon Associates... more

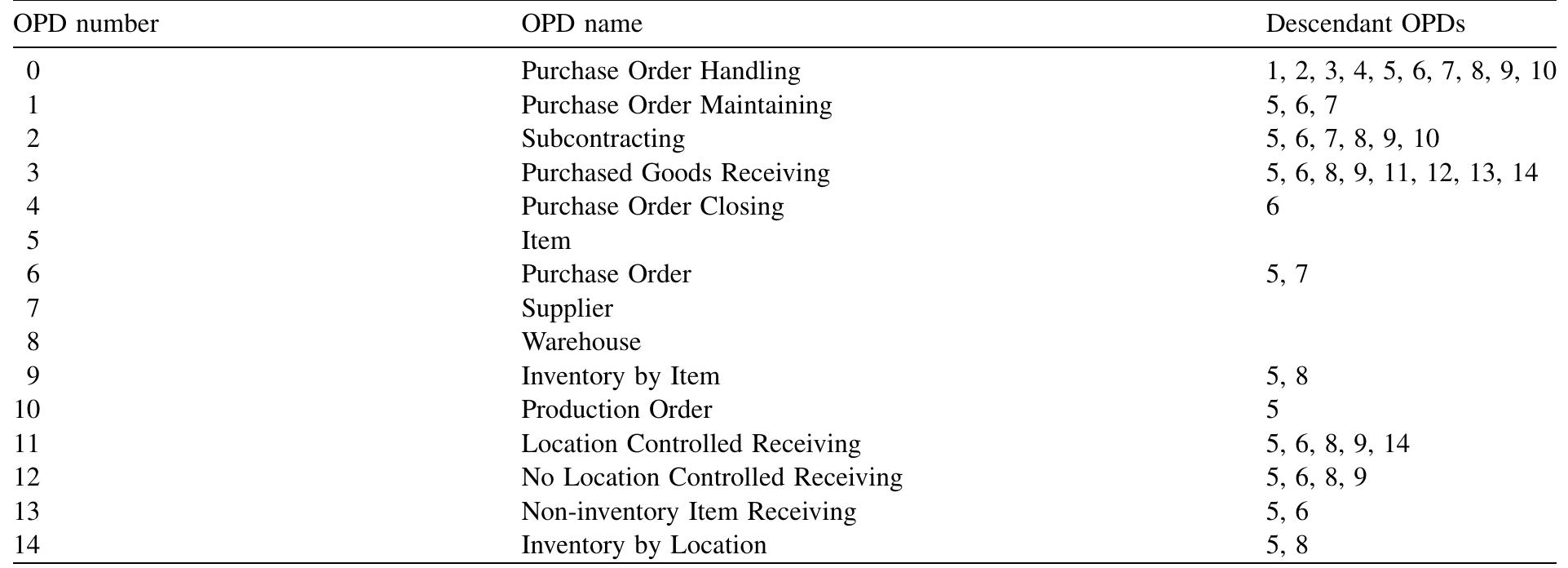

One of the main problems in ERP implementation projects is how to align an off-the-shelf software package with the business processes of the enterprise implementing it. The paper proposes a requirement-driven approach, which benefits from... more

The effect of the cooling rate on hardness and thermal conductivity in a metallurgical Jominy bar made of AISI 1018 steel, by means of a water end-quenched heat treatment process without diffusion-controlled case depth, is studied with... more

In this paper, we describe a new geometric algorithm to determine the biggest feasible cutter size for 2-D milling operations to be performed using a single cutter. In particular:

The force-constancy hypothesis states that the user of a force-feedback device maintains a constant penetration force when stroking virtual surfaces in order to perceive their topography. The hypothesis was developed to address a... more

The dynamics of slender filaments or fibers suspended in Stokesian fluids are fundamental to understanding many flows arising in physics, biology and engineering. Such filaments can have aspect ratios of length to radius ranging from a... more

![TABLE I. Solvent composition, solubility parameter components, and solubility parameter [Hansen (1967)].](https://figures.academia-assets.com/3237997/table_001.jpg)

![TABLE II. Intrinsic viscosity ([7]), Huggins coefficient (ky), and the difference between Huggins and Kramer coefficient (ky —kx) for modified and unmodified polymers in water/PG cosolvent with different compositions.](https://figures.academia-assets.com/3237997/table_002.jpg)

![Figure 1 View of creativity as a property of a system of individuals, fields and domains Figure 1 depicts the DIFI model where creativity occurs in the relationship between the components of a system [6]. It describes the individual receiving information from the domain and adapting to the constantly changing conditions of a particular field, who evaluates novel ideas and decides to reject or incorporate them into their domain. In general terms, the domain is assumed to transmit information to the person, the person to produce a variation, and the field to include the selected variation to the domain [14].](https://figures.academia-assets.com/3237450/figure_001.jpg)

![Figure 2 (a) A simple two-dimensional representation, Qr, and (b) possible interpretations of an artefact E built as Hamiltonian closed shapes by adopters with individual perception biases. In this system, design artefacts are the product of design behaviour and are the subject of evaluation by adopters. Artefacts are kept simple enough to support reasoning for adoption Jecisions. They are implemented as two-dimensional line representations constrained by 12 ooundary points as shown in Figure 2(a). This is a simple way of visually representing features of design artefacts with nomological constraints [15]. This simple design task is a ype of layout problem with negotiable constraints, delayed feedback, cumulative solutions, and with a range of acceptable solutions that depend on different viewpoints. Multiple ‘epresentations and ambiguity are possible because these types of artefacts are perceived and interpreted by evaluators according to a set of randomly distributed perception biases. Figure 2(b) shows sample perceived features of an artefact. The assumption is that people perceive and base their evaluations on different features of design products.](https://figures.academia-assets.com/3237450/figure_002.jpg)

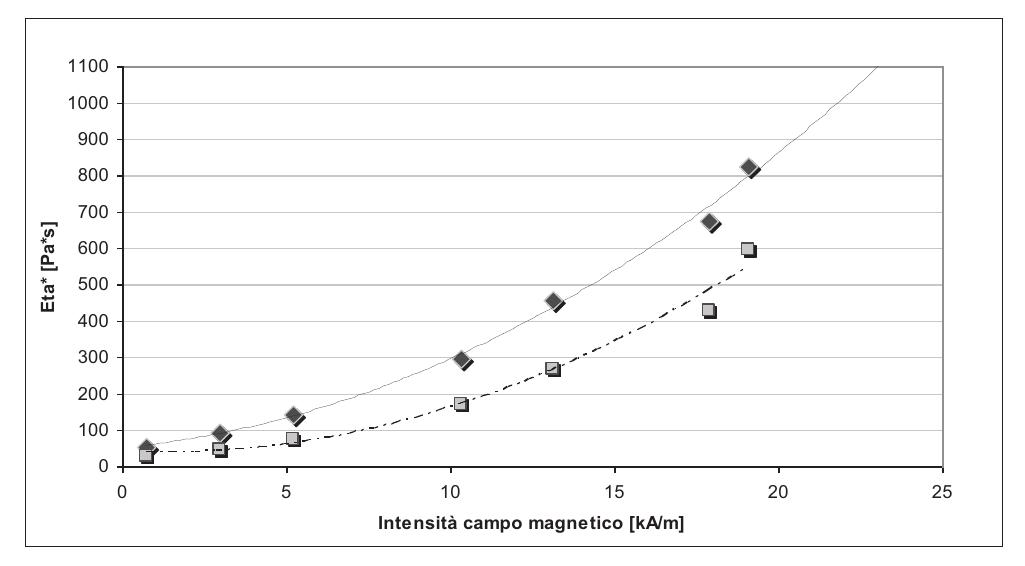

![Figure 2 shows G’, G’’, and Eta * are very sensitive to magnetic field. Rather G’ and G’ increase with the frequency. The storage modulus G’ magnitude can reach values as 6028.42 Pa with a coil current of I= 0.1 A (10,705 kA/m Magnetic field strength) and a driving frequency of 100 rad / sec, while in the absence of magnetic field the value of G’ is equal to 836.52 Pa. The loss modulus G”’ shows a similar trend. The Eta* trend shows that the fluid has a shear-thinnig behavior, which is typical of polymeric materials, we have, in fact, a decrease of viscosity with the increasing of angular velocity [7]. The chain structures or column of iron powder become more stable by increasing the magnetic field, improving the viscosity of one magnitude order. The FMR-ford 50+10 shows a viscosity slightly higher than the FMR-lord, but it shows a higher hysteresis when the magnetic field stops.](https://figures.academia-assets.com/939658/figure_002.jpg)

![Fig. 2. The system model hypergraph of the Purchase Order Handling module, Top level OPD (OPDO) is detailed in Fig. la OPDs of other sub- processes is provided in Table 1. The ERP system model is a vehicle for aligning the system with the enterprise requirements. As such, it should represent the entire scope of options and business process variants supported by the system and represent dependencies among alternative options. Some ERP packages, such as SAP and Baan, provide modeling tools and solution models as part of the system [4,43]. We decided not to use these models as a basis for our alignment approach, since relying on a model that resides within a specific package would decrease the genericity of the approach. Furthermore, while these models serve the purpose of ERP representation, they are not necessarily suitable for specifying the requirements (see, for example, the evaluation of EPC, a language used by the SAP models, in [41]). Therefore, consistent with the requirements model, the ERP system model we use is an OPM model. It is obtained through a reverse The structure of the OPD set can be presented as a graph, called the system model hypergraph, where each OPD is a node with arcs connecting it to descendant OPDs that expose details of one or more of the entities in the parent OPD. One or more arcs can go from each node to its descendant diagrams. Each OPD in the OPD set (except the root, i.e., the top-leve OPD) results from refining an entity of a parent OPD and therefore has an incoming arc connecting it to that parent. Since the origin entity may appear in severa OPDs, more than one arc may lead to each node. The hypergraph is therefore a directed graph (but not necessarily a tree). Fig. 2 is the system mode](https://figures.academia-assets.com/92407/figure_002.jpg)