Lifetime Models for Lithium-ion Batteries used in Virtual Power Plant Applications

2014

…

275 pages

1 file

Sign up for access to the world's latest research

Abstract

defence-bydaniel-ioan-stroe-on-lifetime-models-for-lithium-ion-batteries-used-in-virtual-power-plant-applications.cid131015 Copyright and moral rights for the publications made accessible in the public portal are retained by the authors and/or other copyright owners and it is a condition of accessing publications that users recognise and abide by the legal requirements associated with these rights. -Users may download and print one copy of any publication from the public portal for the purpose of private study or research. -You may not further distribute the material or use it for any profit-making activity or commercial gain

Figures (383)

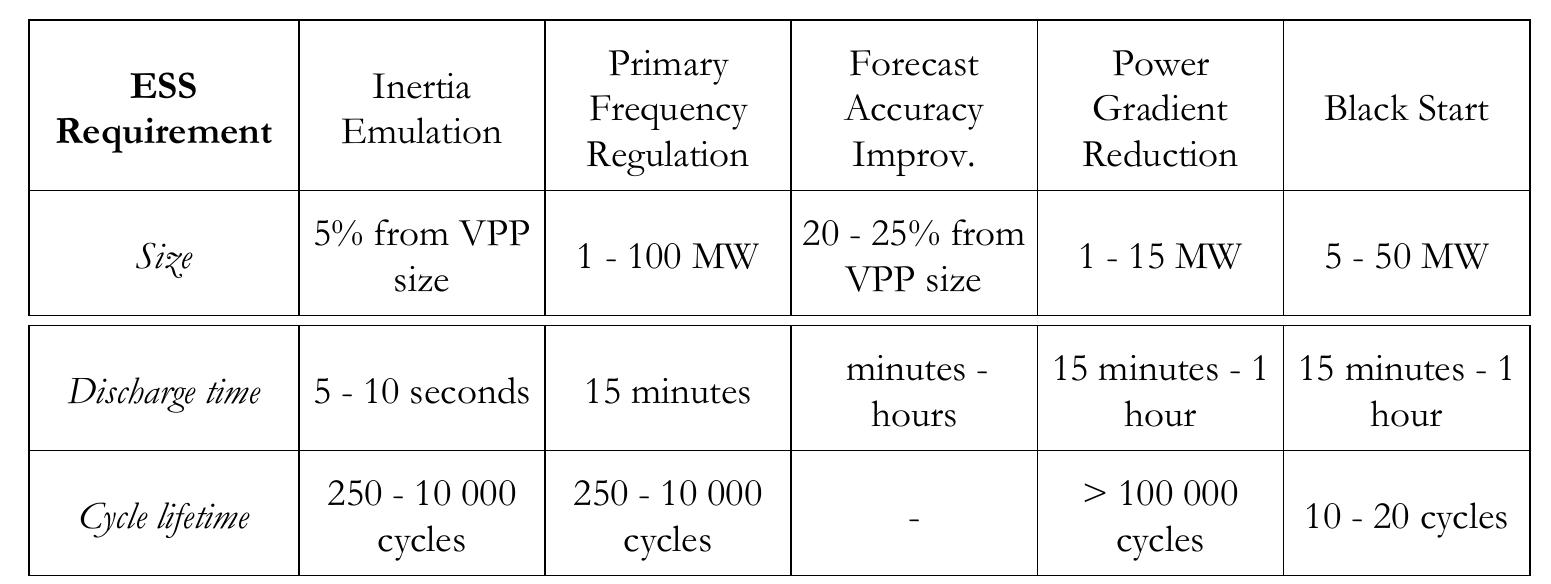

![schematic representation of the VPP concept is illustrated in Fig. 1.3. By integrating ESSs within WPPs, the output power of the new system, further referee: as virtual power plant (VPP), will become mote dispatchable, predictable, and less var able [5]. Consequently, the VPP will behave similar to today's CGUs, seen from the tran: mission system operator's perspective, and will be able to meet future more stringent eri codes, which will ask for more flexibility from the WPPs side [22], [23]. Moreover, th VPP will be able to provide ancillary services such as inertia [20], primary frequenc regulation [24], and will be able to reduce the wind power forecast error [25], [26]. Th schematic representation of the VPP concept is illustrated in Fig. 1.3.](https://figures.academia-assets.com/89071406/figure_003.jpg)

![Table 2.4: Comparison of Li-ion battery chemistries from various perspectives (legend: "++" denotes very good p a4 perp S DS performance, "+" denotes good performance, "-" denotes acceptable performance, "--" denotes low performance) [33], I87].](https://figures.academia-assets.com/89071406/table_002.jpg)

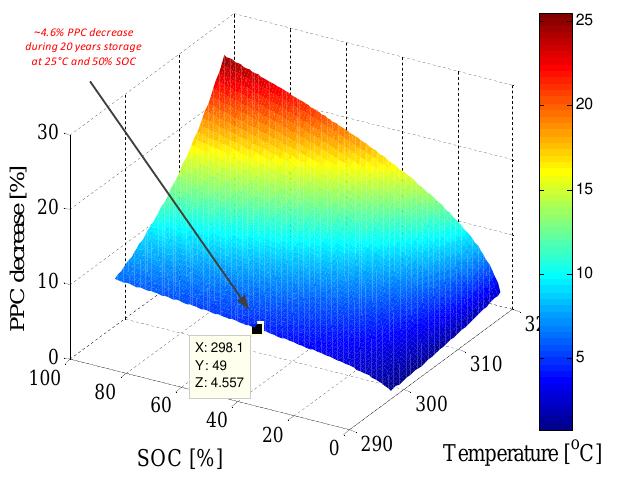

![Figure 3.20: Charging PPC of the LFP/C battery Fi cell measured for the entire SOC range at various tem- ce peratures (measurements performed with nominal current, tu 2.5 A). A PPC values were calculated for a battery current value equivalent to 1C-rate (i.e. 2.54) As a consequence of the flat charge and discharge voltage curves [84], [95], the mea-](https://figures.academia-assets.com/89071406/figure_027.jpg)

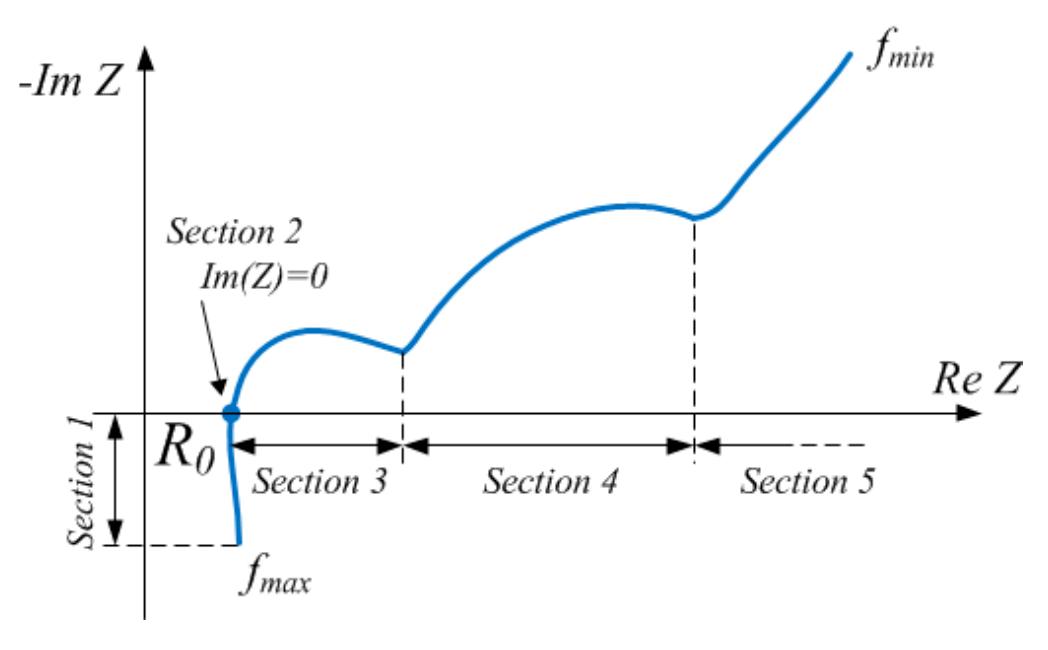

![Table 3.4: Comparison between the curve fitting results obtained for the tvo considered EEC configurations As shown in Table 3.4, the EEC based on ZARC elements is able to fit better dower NRMSE) the impedance spectra of the tested LFP/C than the EEC configuration based on RC networks. The better fitting accuracy is mainly due to the use of ZARC ele- ments, which are able to fit better the depressed semi-circles, which are characteristics for Nyquist curves measured on Li-ion batteries [99], [112]. Consequently, the EEC con- figuration based on ZARC elements was used to fit all the measured impedance spectra (at different conditions) and to model the performance behaviour of the tested LFP/C battery cell.](https://figures.academia-assets.com/89071406/table_005.jpg)

![Table 4.1: Ageing mechanisms of graphite based Li-ion batteries [124], [125]](https://figures.academia-assets.com/89071406/table_008.jpg)

![Figure 4.5: Schematic representation of EEC configuration for lifetime modelling of Li-ion battery cells considering the dependence of EEC parameters on the operating conditions. is presented. [he second group of performance-degradation models ate the EEC-based lifetime mod- ‘Is. The characteristics, structure, and parametrization approach of an EEC-based model vere presented throughout Chapter 3. The EEC-based lifetime models are obtained by idding the "ageing-dimension" to the EEC-based performance models; thus, in order to epresent the ageing behaviour of the Li-ion battery cell, the values of the parameters of he EEC are updated while the ageing process evolves [39], [133]. In Fig. 4.5, a possible onfiguration of an EEC, which considers the dependence on the parameters on ageing Cc nrecenten](https://figures.academia-assets.com/89071406/figure_059.jpg)

Related papers

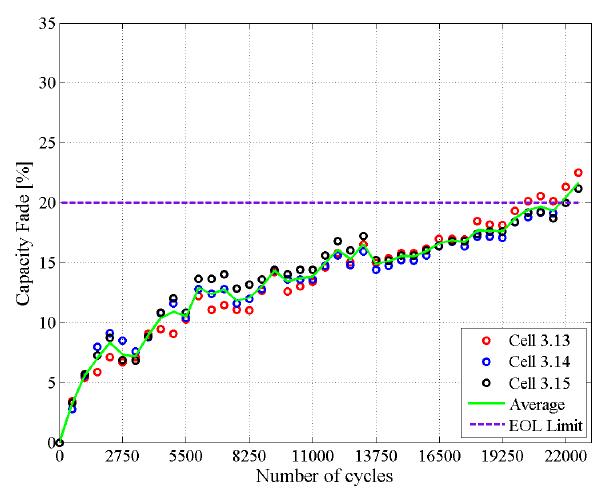

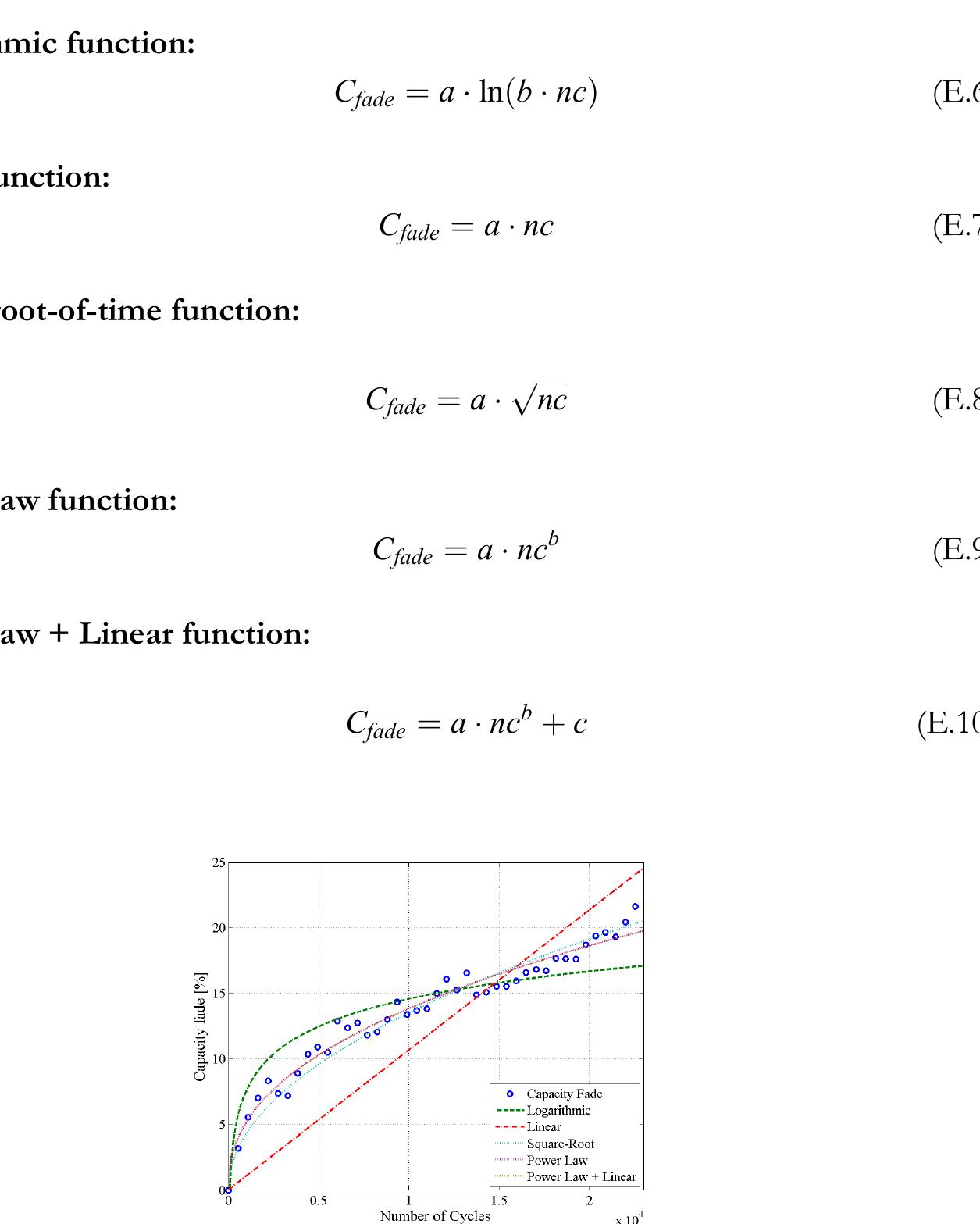

A first-principles-based charge-discharge model was developed to simulate the capacity fade of Li-ion batteries. The model is based on the loss of active lithium ions due to solvent reduction reaction and on the rise of the anode film resistance. The effect of parameters such as exchange current density, depth of discharge DOD, end of charge voltage, film resistance, and the overvoltage of parasitic reaction were studied quantitatively. The model controls the required DOD by controlling the discharge time and estimates the end of discharge voltages as a function of cycle number. Accelerated cycle life testing and developing correlations based on this data are critical for the capacity fade evaluation of batteries. 1-3 Darling and Newman 4 made a first attempt to model the parasitic reactions in lithium-ion batteries by incorporating a solvent oxidation into a lithium-ion battery model. Spotnitz 5 developed polynomial expressions for estimation of irreversible and reversible capacity loss due to solid electrolyte interphace SEI film growth and dissolution in lithium-ion batteries. Ramadass et al. 6 developed a capacity fade prediction model for Li-ion cells based on a semi-empirical approach. Recently, Christensen and Newman 7 simulated the influence of the anode film resistance on the charge/discharge performance of a lithium-ion battery. In this model the loss of reversible lithium ions and increase in the anode film resistance were incorporated into the first-principles model developed by Doyle et al. 8 Process parameters such as charge rate CR, the depth of discharge DOD, end-of-charge voltage EOCV, and the discharge rate DR which influence the capacity fade 9 were not considered in the above-mentioned models. We developed a first-principles-based model to simulate the capacity fade of Li-ion batteries in which incorporation of a continuous occurrence of the solvent reduction reaction during constant current and constant voltage CC-CV charging explains the capacity fade of the battery. 10 Initially the model estimates the capacity fade parameters as a function of cycle number. Next it is necessary to run the lithium-ion intercalation model with the updated parameters to estimate the performance of the battery at a specific cycle number. However, to run both models takes a long computational time. Also, the model does not consider the discharge process, which leads to inaccurate estimation of the total reaction time for the parasitic reaction. In this paper, a charge-discharge capacity fade model was developed based on the loss of active lithium ions due to solvent reduction reaction. The rise of the surface film resistance at the anode due to the parasitic reaction occurring was also considered in the model. The model considers process parameters such as: CR, DOD, EOCV, and the DR. It controls the required DOD by controlling the discharge time and estimates the discharge voltage as a function of cycle number. To decrease the computational time, the transport of lithium in the liquid phase was neglected. It takes only 10 h using a computer with 2.0 GHz CPU and 512 Mb RAM to run the model and to estimate the capacity fade and the charge-discharge performance of a battery cycled up to 2000 times. Model Development The simulations were carried out based on the experimental data obtained for a pouch lithium-ion cell 2.187 Ah, which consists of Li x CoO 2 positive electrode and mesocarbon microbead MCMB negative electrode. The charge-discharge simulations were performed by using a direct charge current of 0.334 A to a specified EOCV of 4.0 or 4.2 V. Next, the voltage was held constant until the charge current decreased to 50 mA. Subsequently, the battery was discharged under a direct current of 0.835 A to a specified DOD of 0.4 or 0.6. There was no rest time between charging and discharging. For simulation of the capacity check, the battery was initially discharged using a discharge current of 0.835 A to 3.0 V. Next, the battery was charged by applying a conventional CC-CV protocol 0.334 A to 4.2 V with a 50 mA cutoff current. The fully charged battery was discharged for second time to 3.0 V. The value of discharge capacity estimated in the second discharge process was used for capacity fade analysis. Both charge-discharge and the capacity check simulations terminate when the battery reaches a voltage lower than 3.0 V. As shown in Fig. 1, during discharge, the lithium ions deinterca-late from the negative electrode and intercalate into the positive electrode. Inside the porous electrode, the intercalation/ deintercalation processes take place at the electrode/electrolyte interface. A rigorous model based on porous electrode theory, concentrated solution theory, Ohm's law, and intercalation/deintercalation kinetics was developed previously which simulates the galvanostatic charge/discharge behavior of a Li-ion rechargeable battery. 8 In the model suggested in this paper, the variation of Li concentration in the liquid phase along the current path was neglected because low-to-medium charge/discharge currents were used in the simulations. The variation in the solid phase potential at the anode or at the cathode is negligible because of good conductivity of the electrode materials. It was also assumed that the active electrode materials are made from uniform spherical particles with a radius of R i and that the diffusion is the only mechanism of lithium transport inside the particles. The direction normal to the surface of the particles was taken to be the r-direction. The model equation that describes the diffusion of lithium in the solid phase is given by Fick's 2nd law

2003

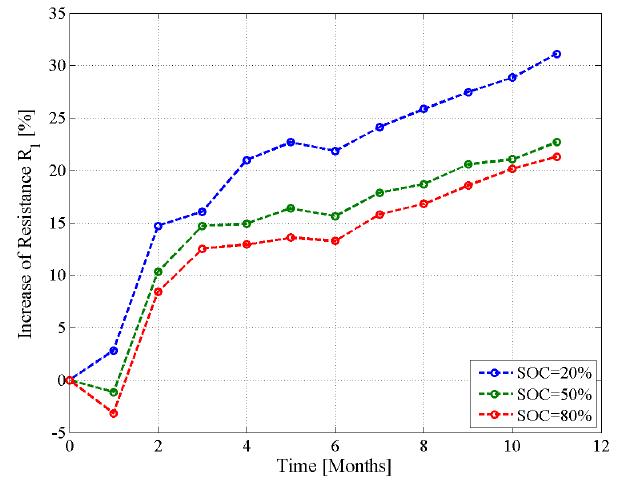

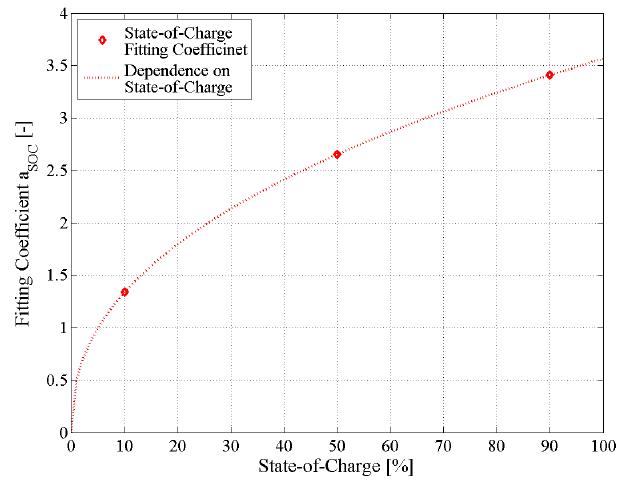

Re´sume´-É valuation expe´rimentale de la dure´e de vie de la batterie dans le programme de recherche SIMSTOCK -La stabilite´dans le temps des performances des syste`mes embarque´s de stockage d'e´nergie (Energy Storage Systems, ESS) est un enjeu majeur pour une diffusion massive et le succe`s des ve´hicules e´lectrifie´s, hybrides et e´lectriques. L'affaiblissement de la capacite´et l'augmentation de la re´sistance interne due au vieillissement affecteront directement l'autonomie du ve´hicule et ses performances. Par conse´quent, la pre´vision du vieillissement des ESS reste un domaine important de recherche. Atteindre cet objectif implique des recherches fondamentales sur les mate´riaux, l'expe´rimentation, la simulation et la conception. Ce papier de´crit les principaux re´sultats du programme de recherche collaboratif SIMSTOCK qui s'est de´roule´pendant 3,5 anne´es avec un budget de 4,2 M € et qui s'est termine´a`l'automne 2011. Ce programme a implique´15 partenaires parmi lesquels, des laboratoires de recherche, des fabricants d'ESS, des fournisseurs de composants de ve´hicules et des constructeurs automobiles et il a be´ne´ficie´du soutien de l'ADEME. Cet article se concentre principalement sur la mode´lisation et la simulation d'une cellule lithium-ion haute puissance teste´e dans ce programme. En premier lieu, est de´crit l'e´laboration d'un mode`le nume´rique de circuit e´lectrique e´quivalent de la batterie, associe´a`un outil de calibration et a`sa validation expe´rimentale. En second, sont pre´sente´es la construction d'un plan d'expe´riences, son utilisation et sa validation, pour la de´finition des expressions mathe´matiques repre´sentant les e´volutions des parame`tres du mode`le de batterie en fonction du vieillissement de la batterie. Ensuite le papier de´taille la me´thode mathe´matique cre´e´e dans le but de prendre en compte le cycle et les effets calendaires sur les caracte´ristiques de la batterie lors des expe´riences sur bancs. Enfin, le mode`le de batterie est inte´gre´dans un mode`le complet du ve´hicule hybride dans la plateforme de simulation Imagine Lab AMESim, afin de de´terminer, avec des conditions de conduite re´alistes, l'impact du vieillissement de la batterie sur la performance du ve´hicule et la consommation de carburant.

An approach to predict the remaining lifetime of lead-acid battery is described. The battery is used to provide back-up power to keep essential devices within wind turbine generators operational under emergency conditions. The approach is developed from a circuit model of the battery. From the results of laboratory tests, changes in the model parametric values due to ambient temperature variations, battery aging effects as well as discharge current level have been quantified. Through a developed computational method, the terminal voltage and state of charge of the battery at any other discharging conditions can then be calculated. The discharge profile allows one to predict the remaining lifetime of the battery. The predicted results appear to agree most satisfactorily with that obtained from laboratory measurements.

Energies

Lithium-ion batteries (LIBs) from electrified vehicles (EVs) that have reached the automotive end of life (EoL) may provide a low-cost, highly available energy storage solution for grid-connected systems, such as peak shaving and ancillary services. There are several issues related to the integration of second life batteries (SLBs) in power systems, such as the variability of the pack design and cell chemistry, in-field assessments of the state of health (SoH), and estimations of the expected lifetimes of SLBs in different power system applications. Model-based approaches are commonly used in the automotive industry for estimating/predicting the capacity and power fade trajectories of LIBs during their life. However, a large variety of models are available with different fidelities, complexities, and computational costs. The accuracy of these estimations is critical for the derivation of business models for SLB applications. This paper presents a qualitative and quantitative assessm...

2020 IEEE International Conference on Environment and Electrical Engineering and 2020 IEEE Industrial and Commercial Power Systems Europe (EEEIC / I&CPS Europe), 2020

The aging behavior of lithium cell has a profound impact on its performance in terms of energy and power efficiency, especially when it is considered in End Of Life (EOL) in automotive field. Lithium battery is considered in EOL if at 85-80% of nominal capacity. Today, the reusing of Electric and Hybrid Vehicles EOL batteries on stationary applications, giving a second life to these batteries, is a solution to reduce high potential cost of lithium batteries. Currently, there is a lack of investigation of the performances of these second life batteries. This paper depicts the performance results of five NMC cells at different SOH, where four of these cells are considered in EOL, so ready to be investigated for possible second use. By results, there are many way to correlate battery SOH and battery performance, e.g. an increase of the internal resistance and the constant-voltage (CV) phase charging duration, the change of the open circuit voltage shape curve. Finally, a battery model based on electrical equivalent circuit is build and implemented in Matlab/Simulink, which is validated by comparison between voltage experimental and simulated data.

Journal of Energy Storage, 2019

Journal of Power Sources, 2006

A rigorous pseudo two-dimensional model to simulate the cycling performance of a lithium ion cell is compared with two simplified models. The advantage of using simplified models is illustrated and their limitations are discussed. It is shown that for 1C or less discharge rates a simple ordinary differential equation (ODE) model can be used to predict accurately the potential as a function of time. For rates higher than 1C, simplifications to the rigorous model are suggested that reduce the solution time for the model.

Journal of Energy Storage , 2018

Due to the increasing interest on the Li-ion battery aging studies among researchers, there are numerous battery degradation models presented in literature. However, they are either focused on a single technology, form factor or scale. This can be challenging for researchers that typically have to bridge multiple technologies and are interested in crossing multiple scales, from material-level, to cell and module/pack level. This paper explores the models presented for Li-ion battery degradation in different scales from the material level to the application level. In each scale, the main aging variables are summarized, the mathematical presentation of models are analyzed and the merits and disadvantages of each scale is discussed. This review aims at bringing together methods and results for multiple technologies, form factors for the most common Li-ion battery technologies.

Loading Preview

Sorry, preview is currently unavailable. You can download the paper by clicking the button above.

Related papers

Computers & Chemical Engineering, 2011

Oil & Gas Science and Technology – Revue d’IFP Energies nouvelles, 2013

Renewable Energy and Power Quality Journal, 2017

Journal of Power Sources, 2020

Sustainability, 2021

Journal of Power Sources, 2002

2014 Power and Energy Conference at Illinois (PECI), 2014

IEEE Transactions on Power Systems, 2000

IEEE Transactions on Transportation Electrification, 2017

Journal of The Electrochemical Society, 1998

Electrochimica Acta, 2006

International Journal of Energy Research, 2016

Sustainability

Journal of Power Sources, 2016

Computational Mechanics, 2016

Proceedings of the Institution of Mechanical Engineers, Part I: Journal of Systems and Control Engineering, 2018

Interface magazine, 2012

Daniel Stroe

Daniel Stroe