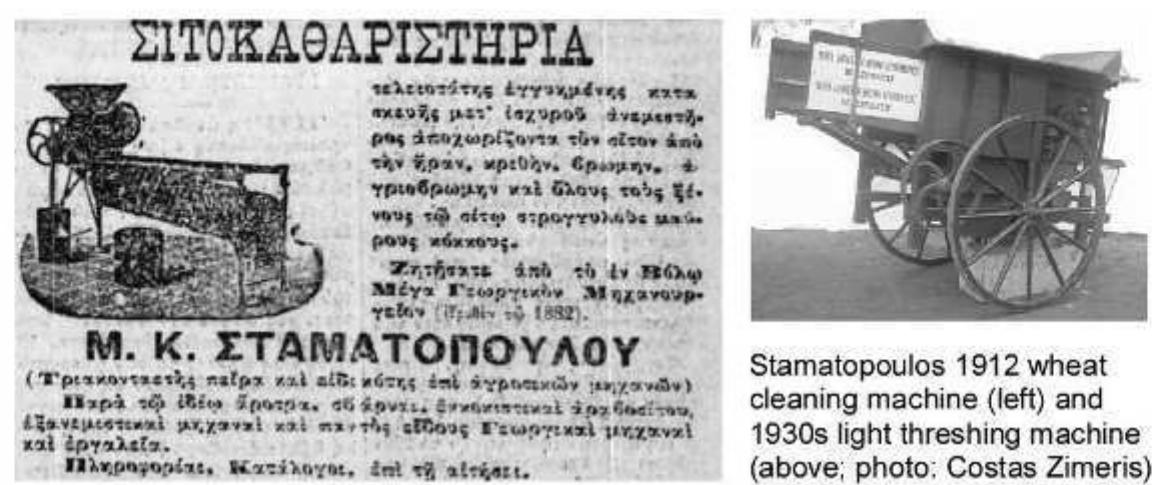

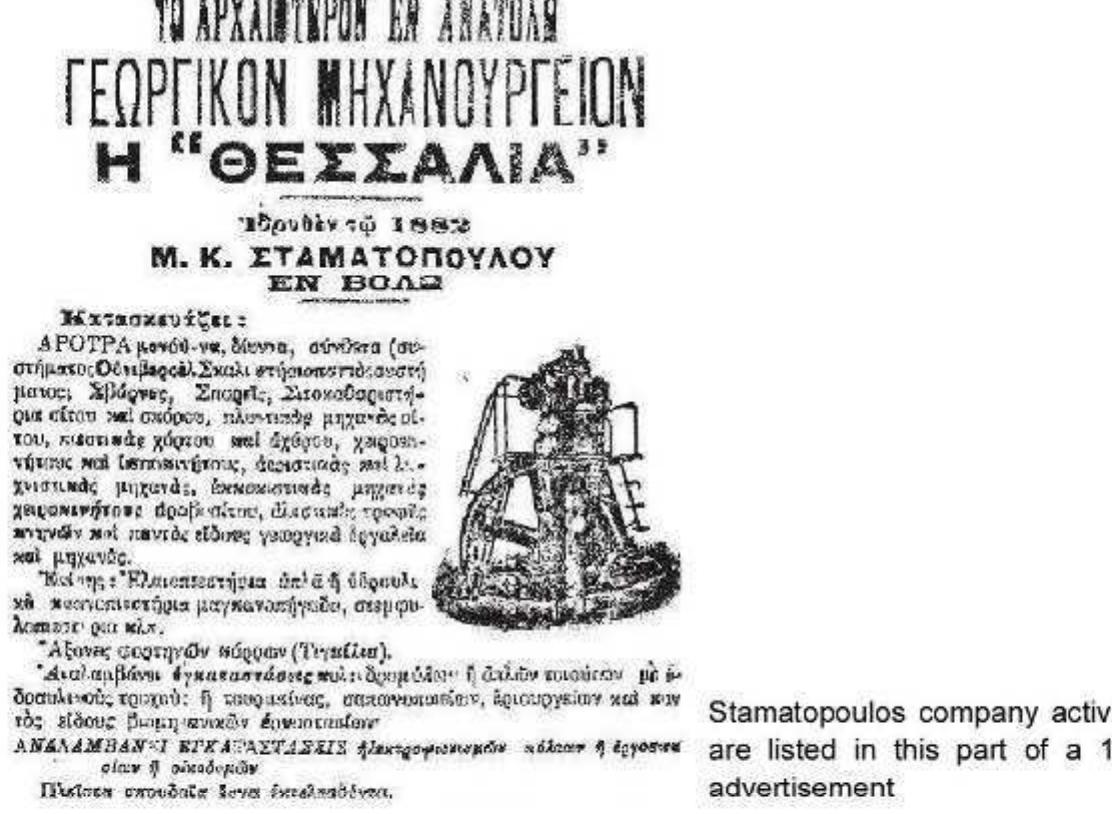

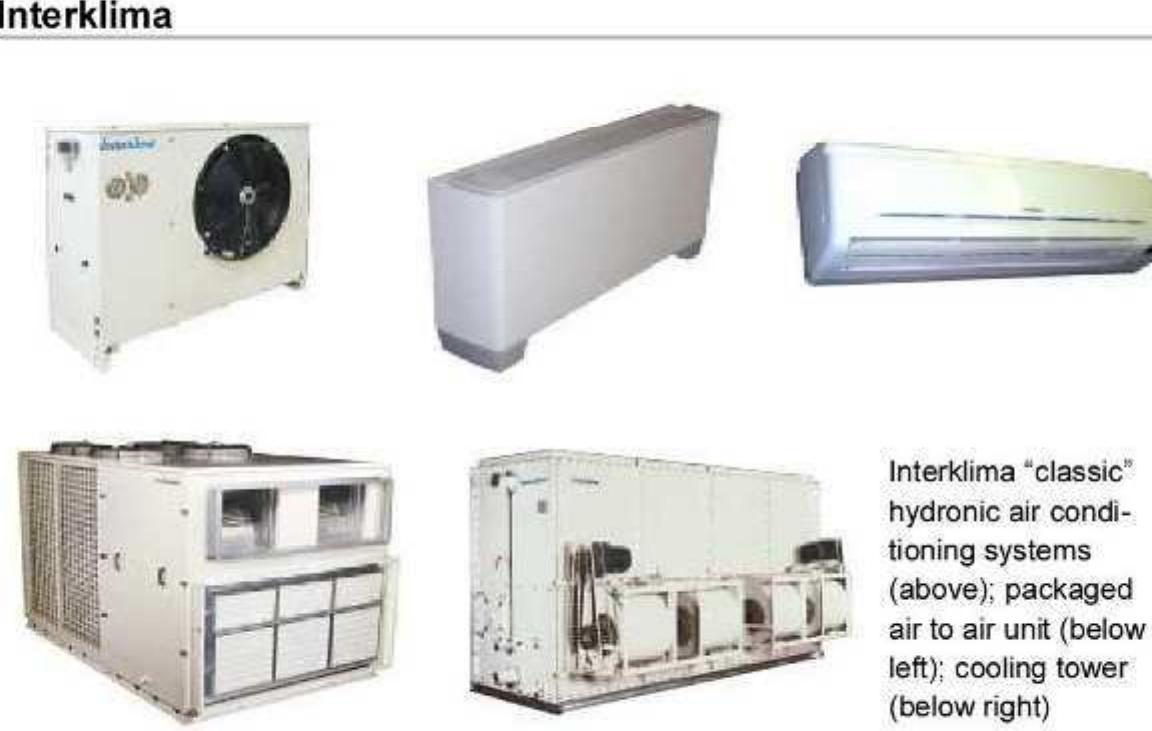

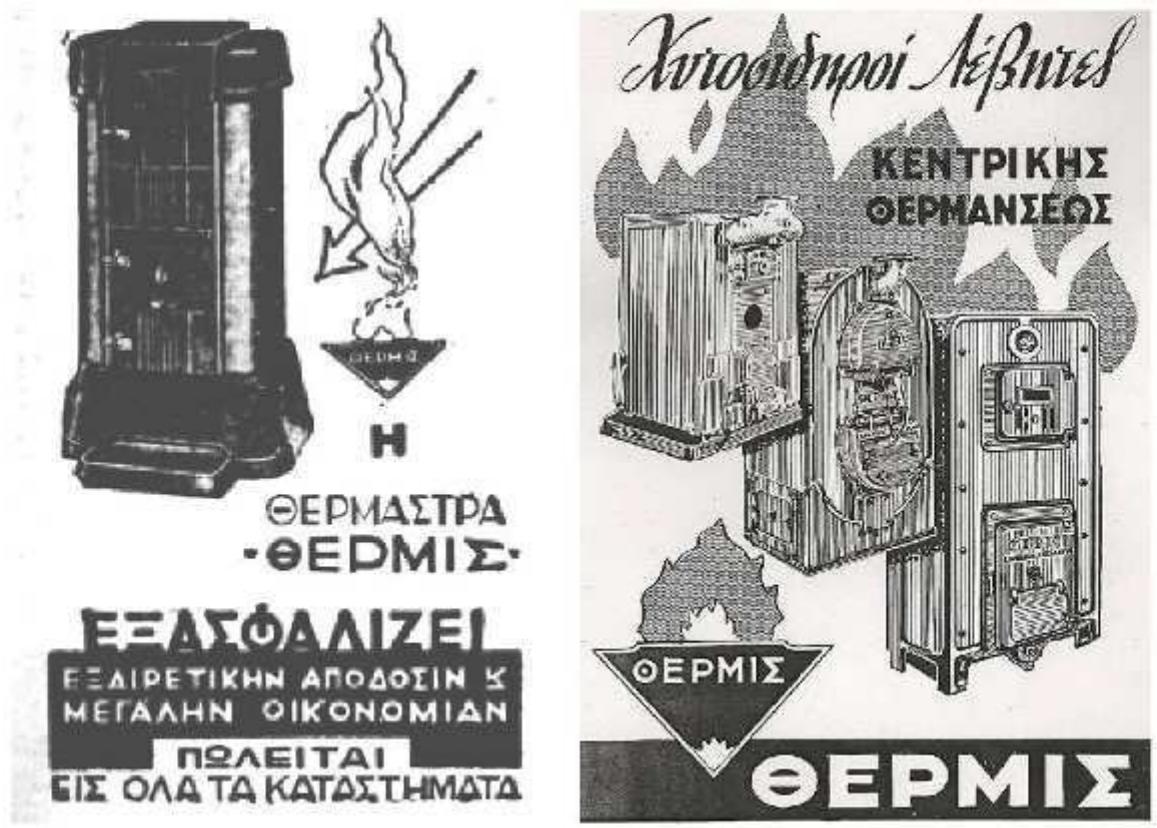

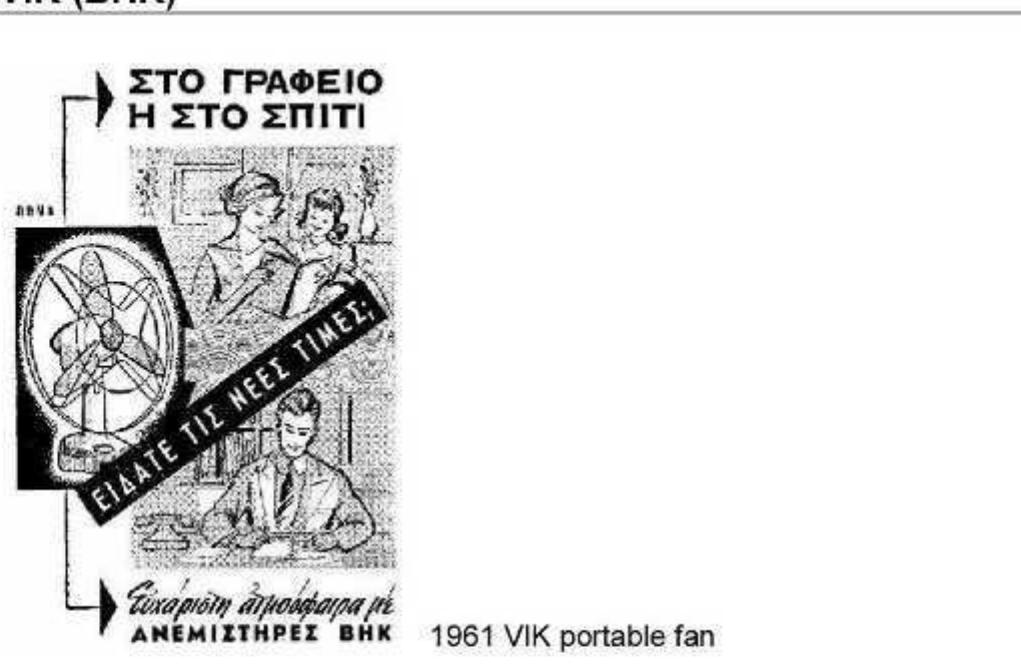

Greek vehicle & machine manufacturers 1800 to present: A pictorial history

2012

Sign up for access to the world's latest research

Abstract

"Few or no records of important elements of Greece’s industrial past exist today, with the increased risk of total “disappearance” of relevant historic memories. In an effort to cover the most characteristic sectors of vehicle and “mechanical products” manufacturing in the country since 1800, an archive collected over a period of over three decades, is utilized in this work. Individual manufacturers and their products are presented, grouped into selected categories, in a concise manner and with the aim to provide an informative, easy reference material. """

Related papers

Enciclopedia del automóvil.

Sociology Study, 2021

It is possible to say that the automotive industries of Argentina, Brazil, and Turkey are each developed as an assembly industry and show great similarities to each other in this context. Since the 1980s, the development direction of the world automotive industry has been trying to make the country's investment environment attractive for foreign international companies to produce in their countries in all three countries. However, with the 1980s, their adaptation to the flexible production system and other new technologies being implemented in the Japanese automotive industry took time, meaning that the learning time took a long time, and local contribution rates fell. This has made the slow development mechanism that has been going on since the past work even slower, and they have suffered the punishment for not being able to develop technologies in all three countries by falling behind in the automotive industry. In the 2000s, with technological advances in electric vehicles, when the use of electric vehicles began to become widespread, we can say that all three countries began to experience a new adaptation problem in the automotive industry more severely. In Turkey, this problem was experienced with all its weight along with the other country; in 2006, the policy of attracting foreign investment to the automotive industry was partially abandoned and the approach to producing domestic cars began to be considered, and in 2011, a decision was made to produce domestic cars. As of December 2019, a prototype of the domestic car has been produced by the automobile initiative group of Turkey and work has started for mass production. Thus, the problem of adaptation to the production of electric vehicles was desired to be overcome by moving to a new stage in the path of technology development. The South Korean automotive industry used this approach in the 1980s and was successful and soon gained the ability to develop technology. In order to see the success of the application of this method in Turkey, it is thought that it is necessary to wait for the result of the domestic car project.

13TH INTERNATIONAL SCIENTIFIC CONFERENCE ON AERONAUTICS, AUTOMOTIVE AND RAILWAY ENGINEERING AND TECHNOLOGIES (BulTrans-2021)

This article is a case study on the analysis and evaluation of the technology used in the process of production some elements to car equipment and its impact on the quality. The article aims to answer the question: does the machine used by the surveyed company, due to the current portfolio of modernity of its parts and subassemblies, guarantee the realization of the production process at a high quality level. In this chapter approach to maintenance of technical objects TPM was introduced and coefficients TPM were calculated. The modernity of the part machine was evaluated on the base of ABC technology method with using the Parker scale. According to this method the machine was divided on three sub-assemblies to whom individual parts were assigned.

Autopia: the car and the modern city. Proceedings of the 3rd annual conference of Automotive Historians Australia, 2018

Proceedings of 'Autopia. the car and the modern city', the 3rd annual conference of Automotive Historians Australia held in Melbourne, 2018.

Entreprises et histoire, 2011

Distribution électronique Cairn.info pour ESKA. © ESKA. Tous droits réservés pour tous pays. La reproduction ou représentation de cet article, notamment par photocopie, n'est autorisée que dans les limites des conditions générales d'utilisation du site ou, le cas échéant, des conditions générales de la licence souscrite par votre établissement. Toute autre reproduction ou représentation, en tout ou partie, sous quelque forme et de quelque manière que ce soit, est interdite sauf accord préalable et écrit de l'éditeur, en dehors des cas prévus par la législation en vigueur en France. Il est précisé que son stockage dans une base de données est également interdit.

Zapisi, 2017

This study is part of a private research project on the history of defence related industry in Greece, covering the period from the establishment of the Greek state, to about the middle of the 20th century. Obviously this project is very much a long term WIP project, as it intends to elucidate on all aspects of military technology, whether imported from abroad or produced locally.

Research Policy, 2001

The aim of this paper is to study the automobile industry of the largest European countries (France, Germany, Great Britain and Italy) from a sectoral, system perspective. The main relationships within and between the building blocks constituting the automobile technological system (TS) are mapped and evaluated. Some general sectoral properties emerge, which hold in the four countries to a different extent, thus suggesting how the institutional set-up works as a differentiating element. A varied process of change in the different elements of the automobile technological system is detected, which nevertheless results in a relatively stable path of development. The countries considered reveal different patterns of motor vehicles trade specialisation in different geographical areas, with changes over time. Also foreign direct investments show the existence of differentiated internationalisation patterns and outward/inward balances.

The Journal of Transport History, 2017

The license agreement between the Italian Fiat and the Yugoslav Crvena Zastava, signed in 1954, was the first commercial arrangement and enterprise between a Western corporation and a socialist country in the post-war era. The Yugoslav side expected the establishment of the modern automobile industry to have a spin-off effect, helping to modernise the entire industrial sector. However, this ambitious plan failed to materialise, leaving the country with Western-type automobiles, which often fell below even East European quality standards. As it was linked to almost the entire industrial sector, the underperformance of the Yugoslav automobile industry can be understood as both a reason for and indication of a dangerously overstretched political and economic system. In particular, the ‘ethnic key’ policy and so-called workers’ self-management were bottlenecks in reaching successful outcomes, only further fuelling Yugoslav contradictions instead of helping to modernise the Yugoslav economy.

Cahiers d'histoire de l'aluminium, 2009

Dans Cahiers d'histoire de l'aluminium Cahiers d'histoire de l'aluminium 2009/1 (N° 42-43) 2009/1 (N° 42-43), pages 6 à 55 Éditions Institut pour l'histoire de l'aluminium Institut pour l'histoire de l'aluminium

Automotive History Review v.61, 2020

Essays by James Todd Uhlman, Keenan Shimko, John E. Mohr, and Andrew James Clyde Hart

Sociology Study, 2022

Turkey’s automotive industry has begun to occur at a much earlier date compared to other developing countries, through licensing agreements to establish automotive industrial facilities, by importing a kind of technology. Attempts have been made in order to produce the domestic automobile road providing sectoral developments could enter another technology pathway. Moreover, the inventor of a very early date in the Fordist production system, such as 1929 by Ford Motor Company with the license agreement, as if he could provide for setting up production facilities in Istanbul’s company, this bad experience has refrained for years from entering as a manufacturer Ford Motor Turkey market. Thus, while Turkey is an attractive market for car production, on the other hand, sufficient improvement over time in the production of trucks and other automotive products, such as buses has not been achieved. The 1929 experience seems to have been effective in terms of Turkey. Because, it was necessary to wait until 1971 for OYAK and TOFAŞ to establish automobile assembly facility with license agreements. With the start of production of two automotive industry facilities, there has been a significant increase in sectoral production figures, but this increase trend has not been sufficiently supported by the government through the incentive system and in the late 1970s the production of the automotive industry has declined. For the first time in 1961, efforts were made to produce a completely domestic automobile, although the prototype of the revolutionary car was successfully produced, mass production could not be started. Subsequently, the production of the Anadol automobile for the second time was tried by means of technology transfer from multiple sources and the serial production of this automobile continued for a while. However, since fiber glass bodywork was used instead of hair bodywork and export opportunities could not be found, production was stopped completely in the end of 1980s. In the 1980s, automobile production continued in two assembly plants and product diversification was carried out to increase the production volume. In the 1990s, three new assembly facilities, Honda, Toyota and Hyundai, were established and the number of assembly production facilities in the country increased to five and technology loyalty based on technology imports continued. Until 2014, the automotive industry continued to consist of five automobile assembly plants and other automotive products assembly plants. In 2015, it was announced to the public that a new domestic car prototype was produced. It was announced that the project will start mass production in 2019. However, it was determined that the prototype would be re-manufactured at the end of 2019 by making changes in the project and that it would be possible to start mass production in 2022. Thus, it is understood that the efforts to start mass production since 2015 can be concluded in 2022, i.e. 7 years after the first prototype was produced. It can produce prototypes in a short period of four months in Turkey in 1961, as evidenced by an indication of the dependency on a long time wasting which is not technology importation pathway, such as five years. How to break the path of devotion demonstrates that it is a difficult job. Path dependency is thought to result from the education system.

Economics World, 2021

It is possible to say that the automotive industries of Brazil and Turkey have developed as assembly industries and showed great similarities in this context. In the 1980s, in line with the development direction of the world’s automotive industry, Turkey tried to make the country’s investment environment attractive for foreign international companies to produce in their country. We can say that while Brazil created the state incentive system in order to attract foreign investments to its country since the 1950s, it tried to increase its dose with the 1990s. Although, like Turkey, Brazil has thought of producing local cars, the difference between Turkey and Brazil is that it has considered exporting and was able to export not only to South America, but also to African countries. Another difference of Brazil is that it has implemented incentive policies for the automotive sector and has been able to rearrange its incentive elements according to changing conditions. Turkey, on the other hand, has decided to return from the policy of attracting foreign investments to its country since 2006, and in 2011, it was decided to produce domestic automobiles. As of December 2019, a prototype of the domestic car was produced by Turkey’s Automobile Initiative Group and work for mass production began. Thus, the problem of adaptation to electric vehicle production was tried to be overcome by moving to a new phase in the way of technology development. This approach was used by the South Korean automotive industry in the 1980s and it was successful and technology development capability was gained in a short time. In order to see the success of the application of this method in Turkey, it is thought that it is necessary to wait for the result of the domestic automobile project. Brazil, on the other hand, was able to rank high in world automotive industry production with its sectoral incentive policies that can adapt to changing conditions and its structure that considers exports from the past, while Turkey lagged behind. Keywords: automotive industry, lagging industries, gaining technology development capability, path dependency, domestic automobil

Automotive History Review, 2022

An annual publication of the Society of Automotive Historians, John A Heitmann, Editor

Related topics

Loading Preview

Sorry, preview is currently unavailable. You can download the paper by clicking the button above.

Labros Skartsis

Labros Skartsis