ARTIFICIAL NEURAL NETWORKS INDUSTRIAL AND CONTROL ENGINEERING APPLICATIONS

Sign up for access to the world's latest research

Abstract

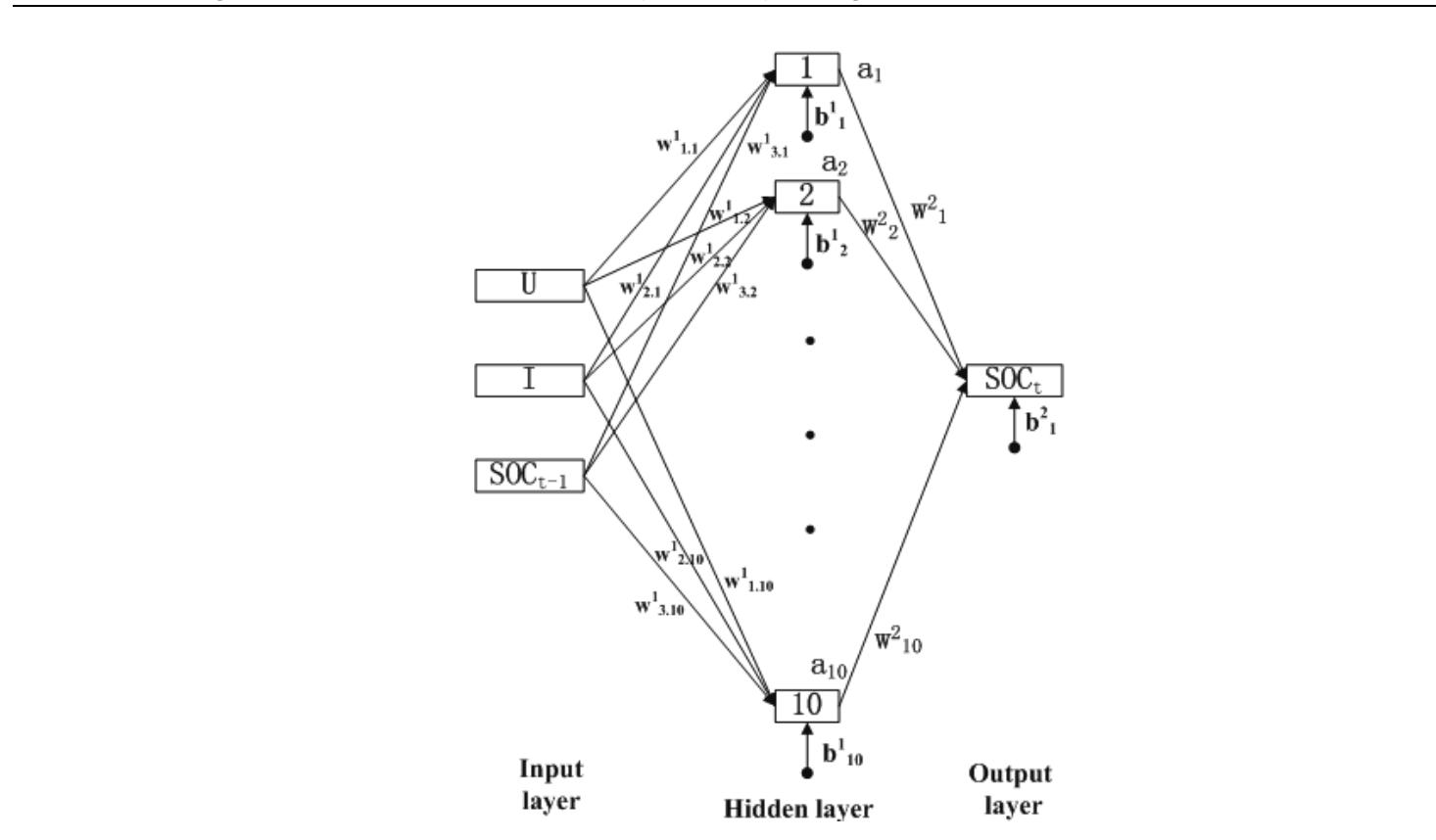

Artificial neural networks may probably be the single most successful technology in the last two decades which has been widely used in a large variety of applications. The purpose of this book is to provide recent advances of artificial neural networks in industrial and control engineering applications. The book begins with a review of applications of artificial neural networks in textile industries. Particular applications in textile industries follow. Parts continue with applications in materials science and industry such as material identification, and estimation of material property and state, food industry such as meat, electric and power industry such as batteries and power systems, mechanical engineering such as engines and machines, and control and robotic engineering such as system control and identification, fault diagnosis systems, and robot manipulation. Thus, this book will be a fundamental source of recent advances and applications of artificial neural networks in industrial and control engineering areas. The target audience includes professors and students in engineering schools, and researchers and engineers in industries.

![presented in [Rivera et al., 1986]. IMC for nonlinear systems is introduced in [Economou et al.,

1986] and IMC with neural networks is described e.g. in [Norgaard et al., 2000].](https://figures.academia-assets.com/54267271/figure_176.jpg)

Related papers

International Journal of Current Microbiology and Applied Sciences

The textile process involves the interaction of a large number of variables. The relations between these variables and the product properties could not be established conclusively. Different techniques have been suggested to determine these relations but with limited success. Artificial Neural Networks (ANN) represent a promising step in this field. In this research, a survey of the application of ANN from fibers through yarn; fabric, garments as well as finishing processes is performed. A comparison between the traditional techniques and ANN in textiles is conducted and a preview for the expected future of ANN in the textile field is also presented.

2015

The artificial neural network (ANN) is increasingly used as a powerful tool for many real world problems. ANN has proved its usefulness for resolving many problems in textiles such as prediction of yarn properties, analysis of fabric defects, process optimization etc. The power of neural networks lies in their ability to represent complex relationships and learn them directly from the data being modeled. The prediction of properties or performance of a process in advance is required to minimize the setup cost and time. The ability to predict these properties accurately has become a challenge due to highly non-linear and interactive behaviour of textile materials. This paper presents basics of ANN and its applications in different textile domains.

Neural Network is an intelligent system that finds widespread applications in many research and engineering fields. Artificial neural network systems is one of the hopes available to textile industry to integrate the elements such as production, quality, cost, information, statistical process control, just-in-time manufacturing computer integrated manufacturing etc,. Artificial Neural Network (ANN) is a field of computer science that seeks to understand and implement computer based technology that can simulate characteristics of human intelligence (that include learning, adapting, reasoning, self-correction and automatic improvement) and human sensory capabilities. Artificial Neural Networks (ANN) are finding applications in textile industry in areas such as fabric engineering, lay planning in garment industry, market prediction, fashion prediction etc The Basics involved in the understanding of the Neural Networks, their properties, construction, Classification - based on application, advantages of neural computing. Next to the basics, Applications of Neural Networks in the area of fabric engineering is covered extensively. To have a clear-cut idea on exactly how the Neural Network works, a real time expert system (using NN) used in Prediction of Fabric end-uses is presented with the principle involved, Prediction network modeling, Training the network, the logic behind the prediction technique etc. Then, the application list extends and covers the use of NN in detecting the fabric faults, grading the color fastness of the fabric, Measurement / Prediction of comfort properties of the fabric.

Neural network is a computational structure. A neural network is a massively parallel distributed processor made up of simple processing units, which has a neural propensity for storing experiential knowledge and making it available for use. It has capability to organize its structural constituents, known as “Neurons”. It can perform certain computations (e.g. fabric pattern, fabric defects, fabric wrinkle, etc.) many times faster than the fastest computer. Artificial Neural Network (ANN) is a field of computer science that seeks to understand and implement computer based technology. The Neural Network is understood on the basis of their properties, construction, classification - based on application, advantages of neural computing. Fabric engineering needs a thorough understanding of the functional properties and their construction parameters. When the relationship between a set of interrelated properties goes beyond the complete comprehension of the human brain, neural networks (NNs) could be used to find the unknown function. Neural network describes the method, for the prediction of both construction and performance parameters of fabrics. Accordingly, constructional parameters are used as input for predicting the performance parameter in forward engineering, and the parameters are reversed for the reverse engineering prediction. Comparison between actual results and predicted results is made. An expert system with an embedded artificial neural network (ANN) is also used, with its functionality toward engineered fabric manufacturing.

… Science & IT …, 2009

Neural Network (NN) has emerged over the years and has made remarkable contribution to the advancement of various fields of endeavor. The purpose of this work is to examine neural networks and their emerging applications in the field of engineering, focusing more on Controls. In this work, we have examined the various architectures of NN and the learning process. The needs for neural networks, training of neural networks, and important algorithms used in realizing neural networks have also been briefly discussed. Neural network application in control engineering has been extensively discussed, whereas its applications in electrical, civil and agricultural engineering were also examined. We concluded by identifying limitations, recent advances and promising future research directions.

IEEE Transactions on Industrial Electronics, 1992

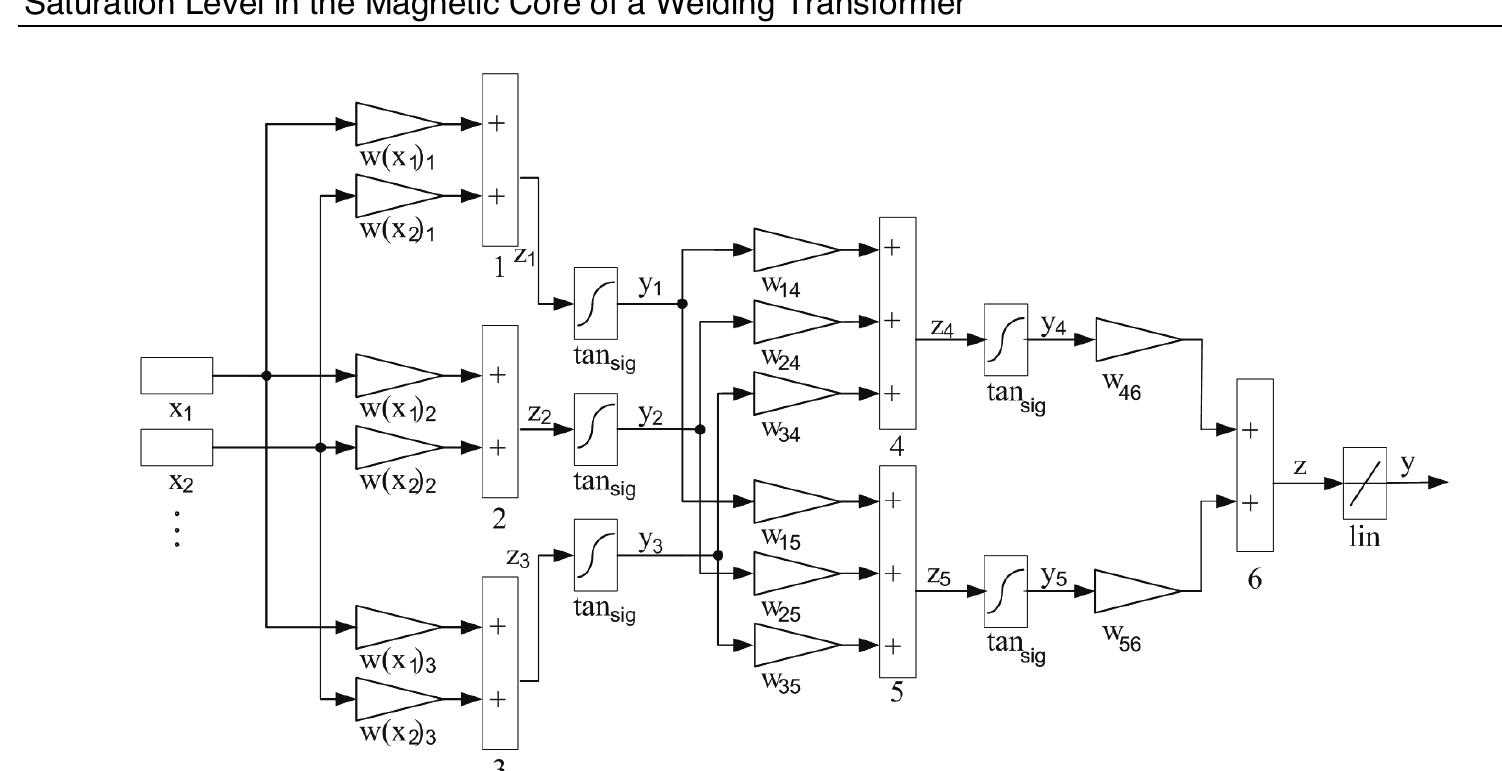

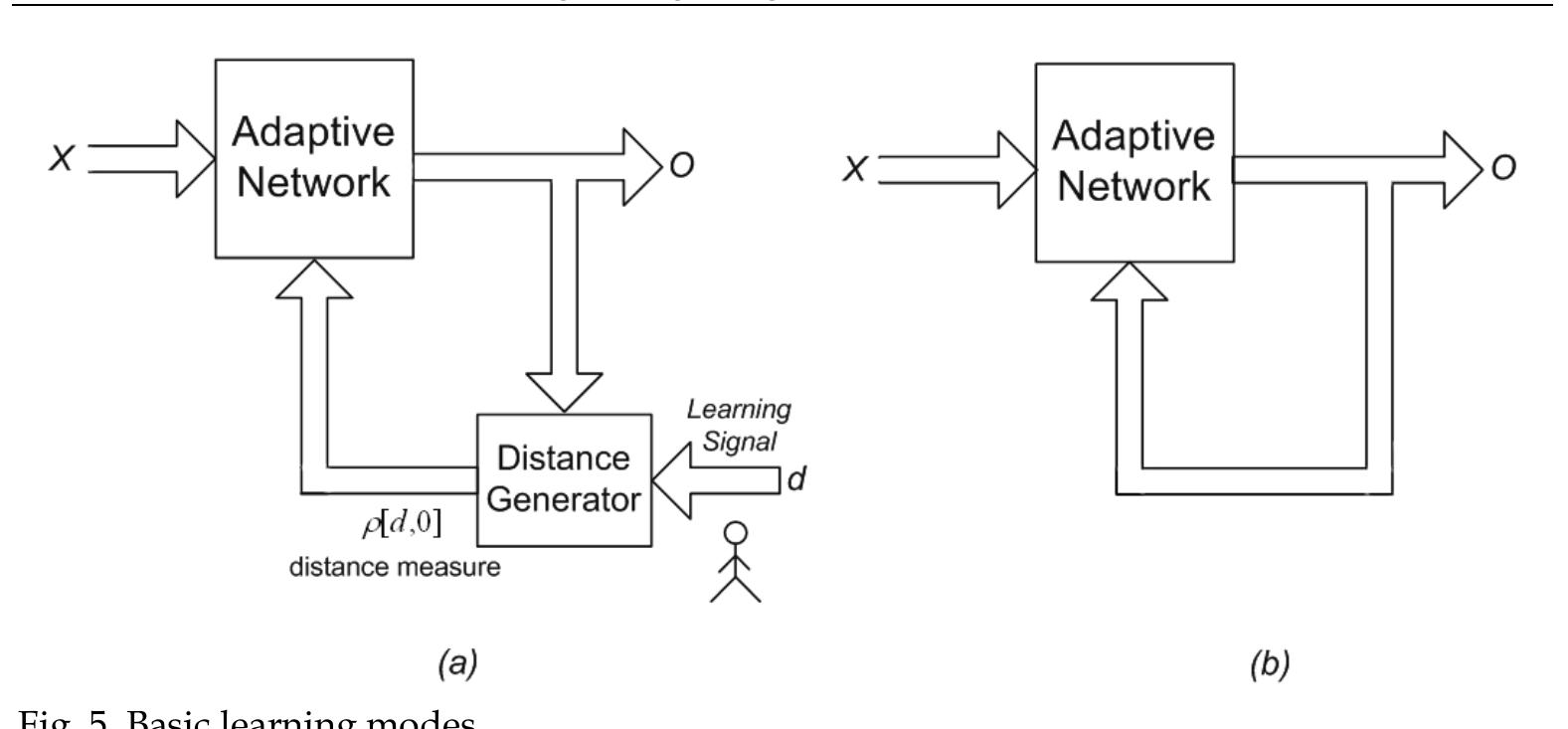

Abstruct-This paper describes the theory and the applications of artificial neural networks, especially in a control field. Artificial neural networks try to mimic the nerve system in a mammalian brain into a mathematical model. Therefore, neural networks have some desirable characteristics and capabilities similar to the brain system, such as parallel processing, learning, nonlinear mapping, and generalization. Recently, many researchers have developed neural networks as new tools in many fields such as pattern recognition, information processing, design, planning, diagnosis, and control. We survey hybrid systems of the neural networks, fuzzy sets, and Artificial Intelligence (AI) technologies. Fuzzy sets and technologies have been also implemented as new tools in many fields and shown to be useful. Therefore, we deal with the hybrid systems as key technologies in the future.

Indonesian Journal of Computer Science, 2022

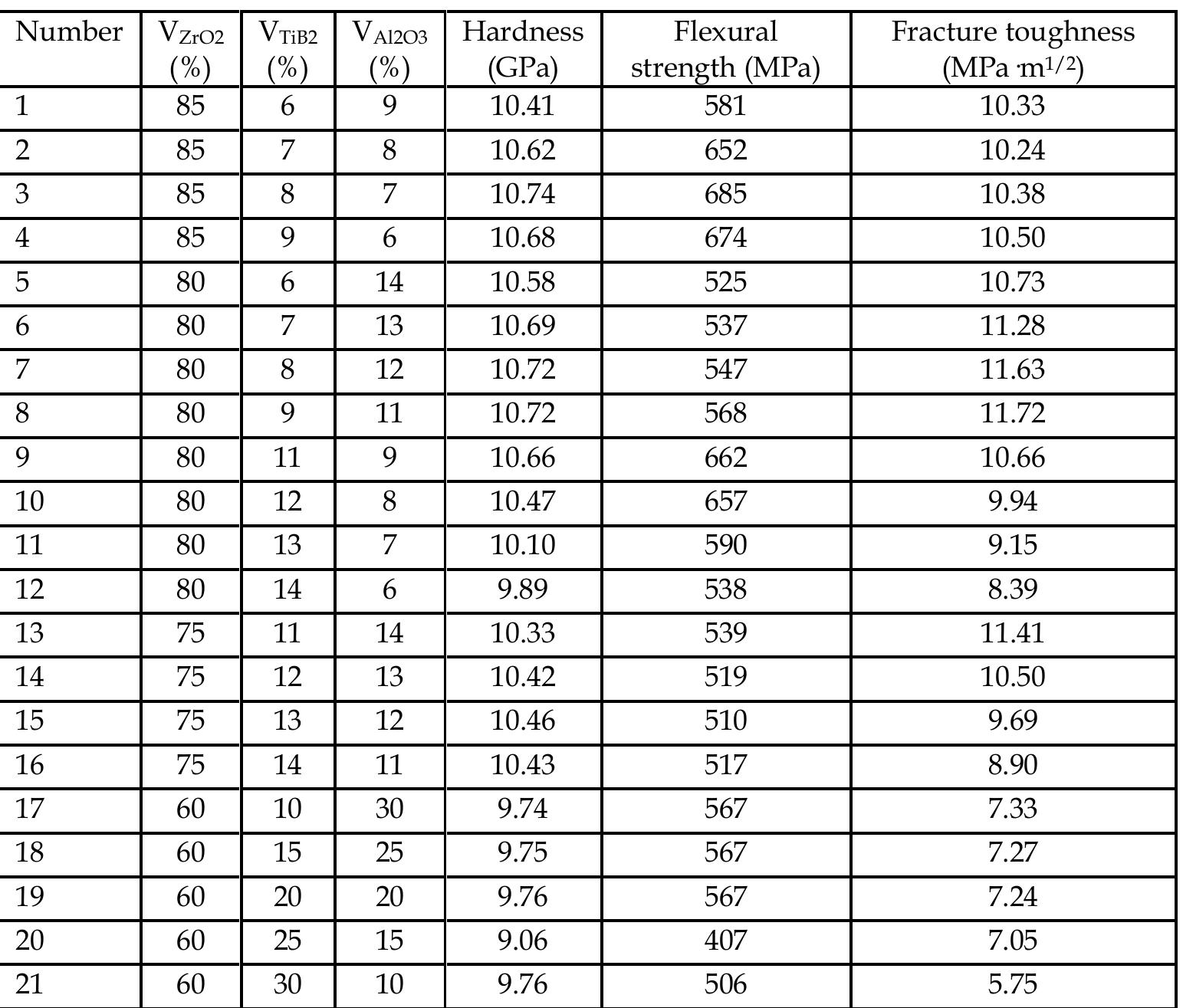

The neural network model is an advanced and effective tool aims at simulating the manufacturing operations. An important number of researchers have utilized artificial neural network (ANN) to optimising multiple response metrics in manufacturing applications. In the majority of situations, the use of ANN enables the prediction of the mechanical and physical properties of manufacturing goods based on provided technical data. To this end, the deployment of ANN in manufacturing sector is tremendously significant in terms of cost and material resource savings. Thus, Artificial neural network as a key component regarding the optimization of the manufacturing processes.

2003

This paper presents a comprehensive review of the industrial applications of artificial neural networks (ANNs), in the last 12 years. Common questions that arise to practitioners and control engineers while deciding how to use NNs for specific industrial tasks are answered. Workable issues regarding implementation details, training and performance evaluation of such algorithms are also discussed, based on a judiciously chronological organization of topologies and training methods effectively used in the past years. The most popular ANN topologies and training methods are listed and briefly discussed, as a reference to the application engineer. Finally, ANN industrial applications are grouped and tabulated by their main functions and what they actually performed on the referenced papers. The authors prepared this paper bearing in mind that an organized and normalized review would be suitable to help industrial managing and operational personnel decide which kind of ANN topology and training method would be adequate for their specific problems.

Computers & Industrial Engineering, 1992

Advanced manufacturing systems are becoming too complex and dynamic for traditional rule-based decision support systems. Neural network technology application is gathering momentum in all aspects of manufacturing processes. This paper overviews the technology and surveys the literature on its application in manufacturing processes.

2000

The potential of the artificial neural networks in the field of wear and manufacturing processes is presented in this paper. Their properties of learning and nonlinear behavior make them useful to model complex nonlinear processes, better than the analytical methods. The neural structures, considered appropriate for such models, are presented. The applications found in the referenced papers mainly consist of prediction and classification. They present some common points, specific to the field: wear processes and particles, manufacturing processes, friction parameters, faults in mechanical structures. The results obtained by the quoted authors, in their interdisciplinary research are described, proving that neural networks are an useful tool during the design stage as well as the running or operation stage.

Advances in Computational Intelligence

In this paper, a new approach is proposed which predicts the output of the dyeing process in textile industry by using input data consisting of the alarms and/or the interventions during the process. Back-propagation algorithms and radial basis functions are utilized to form the neural networks in predicting whether the dye process is carried out correctly or not before an operator checks it manually. Industrial data are used to test the efficiency of the proposed concept which demonstrates that the success rate is over 85%. Keywords: Artificial Neural Network (ANN) • Dye process • Textile industry • Levenberg-Marquardt (LM) • General regression Neural Network (GRNN) • Gradient Descent with an Adaptive Learning Rate (GDA)

Proceedings of 10th World Congress on Computational Mechanics, 2014

The methodology and examples of utilising neural networks for assisting, controlling and designing technological processes is presented in the paper. Examples concern the continuous melting, casting and rolling of aluminium and alloy rod intended for drawing for electrical wires. Neural networks allow to build dependencies between the performance parameter set, chemical composition of the processed material, and product properties. These functions are used for the process control and for determining the optimal work point of the technological line. The initial data constitute the analytical results of the metal chemical composition and process data collected by the specially built system of canvassing realisation parameters of all unit processes. The effectiveness and efficiency of the system was assessed.

Tekstil Ve Konfeksiyon, 2017

In this study, a feedforward backpropagation artificial neural network (ANN) software was developed and it was tested with two different fabric group. While the former was consisted of 29 cotton samples produced under different conditions, the latter was consisted of 49 polyester samples produced under the same conditions. Each group is divided into training and control groups. The result values of the control groups produced by the trained neural network were obtained. The results of the linear regression for both groups with the same method were also obtained. While the fabric weight, thickness, warp and weft tensile strength for the cotton samples are being examined, the air and water permeability values for the polyester samples were examined. Artificial neural network values for all samples showed better fit than linear regression values. ANN and linear regression results were produced closer results for the polyester samples produced under controlled conditions. While ANN results on cotton samples produced under uncontrolled conditions showed good agreement, the fit of the linear regression results deteriorated. This study was supported by the BAP unit of Uşak University.

2014

Artificial Neural Networks along with Image Processing Systems have proven to be successful, particularly in the domains of mathematics, science and technology. They have gained quite notable advantages beyond classical learning, as their usable engagement are observable in many fields of scientific environment related to the relevant systems. This paper presents a model for identifying the small components parts. The model may be significant in various industries mainly in engineering processing system areas. The objective of the study is to apply Artificial Neural Networks (ANN) in Image Processing System (IPS) with feed forward structure to detect, and recognize different parts or any other environment products on a moving conveyor bel. In the proposed model, we have used appropriate method of edge detection. The edge detection realizes artificial neural network with noise. The paper emphasizes the implementation of the model considering functionality, parts images, accurate dete...

Lecture Notes in Computer Science, 2008

In this paper we use a neural network approach for defects identification in textile. The images analyzed came from an artificial vision system that we used to acquire and memorize them in bitmap file format. The vision system is made of two grey scale line scan camera arrays and each array is composed of four CCD cameras with a sensor of 2048 pixels. Every single camera has a field of view of 600mm. The big amount of pixels to be studied to determine whether the texture is defective or not, requires the implementation of some encoding technique to reduce the number of the significant elements. The artificial neural networks (ANN) are manipulated to compress a bitmap that may contain several defects in order to represent it with a number of coefficients that is smaller than the total number of pixel but still enough to identify all kinds of defects classified. An error back propagation algorithm is also used to train the neural network. The proposed technique includes, also, steps to break down large images into smaller windows or array and eliminate redundant information.

Fibres and Textiles in Eastern Europe, 2017

The purpose of the present study was to estimate dimensional measure properties of T-shirts made up of Single Jersey and interlock fabrics through Artificial Neural Networks (ANN). To that end, 72 different types of t-shirts were manufactured under 2 different fabric groups, each was consisting of 2 groups: one with elastane and the other without. Each of these groups were manufactured from six different materials in three different densities through two different knitting techniques of single jersey and interlock. For estimation of dimensional changes in these T-shirts, models including feed-forward, back-propagated, the momentum learning rule and sigmoid transfer function were utilized. As a result of the present study, the ANN system was found to be successful in estimation of pattern measures of garments. The prediction of dimensional properties produced by the neural network model proved to be highly reliable (R2> 0.99).

Journal of Applied Polymer Science, 2008

The performance of an artificial neural network (ANN) is affected by the number and types of inputs. The aim of this article is to study the performance of ANN algorithms, used for the prediction of cotton yarn strength, elongation, and evenness, as the input units are subtracted (skeletonized) and added to the input layer. Nineteen factors, consisting of fiber properties, processing parameters, and yarn quality properties, were used as the main source of inputs. The initial sets of inputs, which were selected on the basis of their relationship with the output factors, were 13, 13, and 12 for yarn strength, elongation, and evenness, respectively. The final sets of inputs were 14 factors for the three yarn quality properties being predicted, and the new ANN algorithms showed performance improvement of 40, 37, and 47% for strength, elongation, and evenness, respectively, when compared to the algorithms with 19 factors. Yarn twist, fiber length, and fiber length uniformity were common among the five most influential factors affecting yarn strength, elongation, and evenness, accounting for 40, 37, and 37% for the prediction of yarn strength, elongation, and evenness, respectively.

Journal of the Textile Institute, 2006

Engineering of spun yarns having specific tensile, evenness and hairiness characteristics is a long-cherished dream of spinning technologists. Selection of suitable raw materials at minimum cost and optimisation of process parameters are the two major tasks to be achieved to manufacture engineered yarn. Advent of high-speed fibre-testing machines and development of powerful modelling tools such as artificial neural network (ANN) have provided a great impetus in the yarn engineering research. This article demonstrates the feasibility of yarn engineering by developing a yarn-to-fibre 'reverse' model, using ANN. This approach is entirely different from the prevailing forward models, which predict the properties of final yarn using the fibre properties as inputs. The cost minimisation of cotton fibre mix was ensured by using the classical linear programming approach in combination with ANN. The engineered yarns demonstrated good agreement with the target yarn properties.

In this paper, a neural network approach is used to understand the effects of HVI fibers characteristics and process parameters on yarn tensile properties, CVm% and hairiness. In this approach, four fibers characteristics, twist level and metric number are taken as input variables and the breaking strength and breaking elongation, CVm and hairiness as output variables. The technique of Bayesian regularization is used for improving the generalization capability of neural networks. For this purpose, five different blends of cotton were processed and spun into ring yarns having different counts. Each count was spun at five twist levels.

Loading Preview

Sorry, preview is currently unavailable. You can download the paper by clicking the button above.

Kenji Suzuki

Kenji Suzuki